New gas sensors control the CO2-containing area

A new touch system for the first time helps control large areas that are cost effective. This patented gas induction system is based on the principle of diffusion, whereby specific gases pass through a membrane faster than other gases.

By using a kind of tubular-like induction machine, this new sensor can measure average gas concentration over a certain distance without affecting or falsifying conditions in the environment. measure.

If these sensors are placed in a separate model, they can calculate gas concentration on an area. Therefore, the measuring tube can replace a large number of personal sensors, making it much cheaper than other previous methods. This sensor was invented by Helmholtz Environmental Research Center (UFZ) and will be published for the first time at the 15th International Trade Fair on Water-Waste-Waste and Recycling (IFAT). takes place from May 5-9 in Munich.

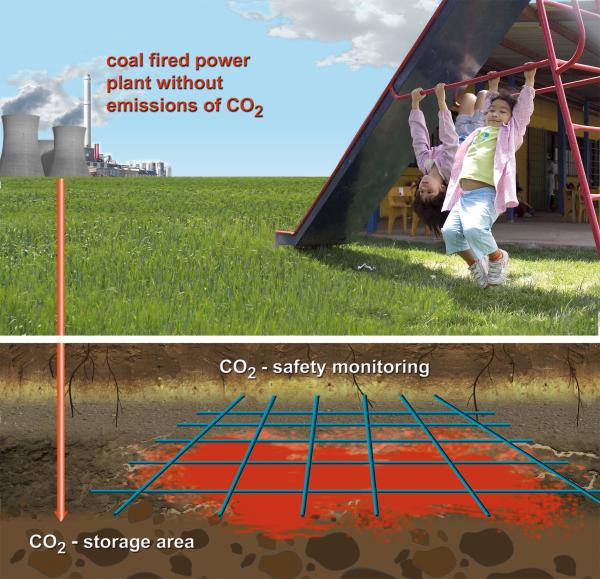

Potential areas of application of membrane sensors based on membrane principles (also known as MeGa) are environmental compensation and landfill control . However, in the future, this technology could also be used to control the transfer of CO2 into the ground, gas lines or gas pipelines. This principle of operation can also be used in solutions, so detectors are also useful for controlling areas of water (eg for observing the formation of hydrogen sulfide gas ( hydrogen sulphide, which contains groundwater, and is useful for controlling cavities in the ground.

Functional principle of membrane air induction machine.The potential application of the new gas induction machine is the control of CO 2 reserves in power plants. (Photo: Susan Waiter / UFZ)

Smaller than normal construction structure of underground cavities and water-based detectors means that this induction machine can be used in detectors. The connection (fixed) to the above ground component helps to assess or capture data while the detector is submerged into the water. To the best of our knowledge, a device with these characteristics has never been anywhere in the world before. Another potential area of application is the control process in the treatment of water or in the food industry, such as breweries and dairy factories.

Researchers are hoping that in the future their system can also contribute to smart ventilation applications of indoor space. The excess of carbon dioxide creates fatigue and health problems, while excess ventilation is a waste of energy. Therefore, in classrooms, conference room types and workplaces, there is a requirement to suggest that the concentration of gas in the room is between 1000 and 3000 ppm units (units due to the density of 1 million). ).

Explained by UFZ Detlef Lazik, 'Until now, the control of gas concentration in the room has failed due to the lack of measurement methods associated with proper ventilation technology and reasonable price. With air induction machines based on our membrane principle, it is possible to create ventilation that is isolated using a ventilator with a controlled gas induction machine. The ventilation is then activated simply if there is an excessively adjustable threshold value '. The same principle can also be used to control hazardous materials in mining, construction and equipment or in tunnels.

The Helmholtz Environmental Research Center (UFZ) will represent at the IFAT 2008 trade fair on Water-Waste-Waste and Recycling in Munich from 5-9, May 2008. Scientists at the showroom of UFZ (Count No. 207) B1 will provide information on operating contaminated areas and present the most advanced environmental technologies and new products. Along with a gas sensor based on the principle of membrane control for CO 2 in areas with water and soil, the UFZ center will present Carbo-Iron (a new material for repair topical treatment), RF-Heating technique (healing of the soil through targeted directional heating) and the Compartment Transfer technique (breaking down dangerous materials using semi-wet marsh models) of course.

- NASA brought high-tech sensors into volcanoes

- Super tracking device

- Developed ultra-thin, transparent, ultra-accurate pressure sensors

- Sensors use electrical energy from insect repellents

- Tires have the ability for the driver to know the road conditions

- Sensors monitor temperature and humidity around plants

- 15 agricultural technologies of the future

- New generation of touch devices

- Sugar sensors help detect and prevent disease

- Attach tiny sensors to honey bees

- Microelectronic sensor on dental diagnosis

- The ability to 'telepathy' is not too far away

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water