3D printers use ink made from sand and glue

An Italian inventor Enrico Dini has developed a three-dimensional (3D) printer called D-Shape. It can print an entire house with sand and artificial glue.

Operation mechanism of the printer: spray a thin layer of thin sand and artificial glue according to a design that is outlined in the computer.

The glue turns sand into a solid rock by building each layer from bottom to top. Thus, the printer can create statues or sand buildings.

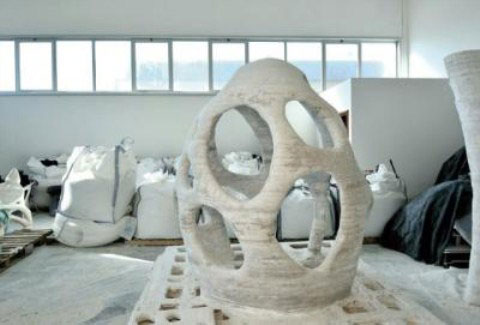

Architectural works with many curved and curved lines made by 3D printers.

The printer can move in a horizontal and vertical column. To conduct one-layer printing, the printer moves up to about 5 to 10 mm.

It is controlled by a computer running Auto CAD program (design support program). Like two-way printers, which use conventional ink, Enrico Dini's 3D printer also has a resolution, specifically 25 dpi.

The resulting product is more rigid than concrete and does not require machining metal.

The structure of 3D printer consists of 1 horizontal bar and four vertical axes.

D-Shape printers can construct models that are four times faster than conventional construction at half the cost.

In addition, this type of printer is very environmentally friendly because it uses less toxic chemicals.

It is worth noting that it can create works with many curves, hollow pipes and columns.

Dini and colleagues work on the computer using CAD software.

Dini is planning to develop D-Shape to build basic buildings. The experiment was conducted at the Alta Space Laboratory, a division of the European space research agency.

- The fastest 3D printers produce smaller copies of sand grain

- Surprised with incredible medical products -

- NASA brings 3D printers to space

- Biological glue gun for wound healing

- Japan invented 'super glue' used underwater

- Where does sand in the sea come from?

- Video: Magic cat, an interesting toy

- Glue helps wound heal after surgery

- Warning the world is about to run out of sand

- Successfully developed gravel glue that breaks down is sticky

- Turn dirty sand into clean sand

- Why can't sand and sea sand be used for construction?

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water