MIT team creates materials that are lighter than plastic and stronger than steel

The MIT team has created an ultra-light material that's four to six times stronger than bulletproof glass, which can be used to protect smartphone screens.

The material, developed by experts at the Massachusetts Institute of Technology, achieves a two-way polymerization reaction, which has been thought impossible for a long time. Polymerization is a process in which small atoms called monomers combine to form long spaghetti-like chains called polymers. Polymer fibers can form three-dimensional objects such as water bottles through injection molding.

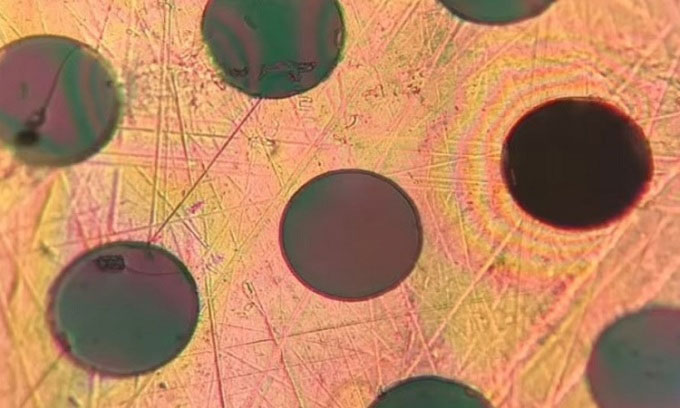

The team stretched the polymer film across the porous surface.

However, the team successfully created a material that self-assembles into a two-dimensional sheet. These sheets, called polyaramides, are stacked on top of each other and held together by extremely strong hydrogen bonds, making the material super-strong. In addition to being used as tempered glass for phones, the polymer could also be used as a protective layer for vehicle parts or large-scale construction materials.

"We don't usually think about using plastic to support a building, but with new materials you can do a lot of things," said Professor Michael Strano, who led the study. "It has a lot of unusual features and we're excited about that."

Polymers formed from two-dimensional sheets can be used to make ultralight materials. However, decades of research have concluded this is not possible in part because as long as one monomer deviates from the growth plane of the entire plate, the entire object will deform. To overcome this problem, the team used melamine compound, made up of carbon and nitrogen rings, commonly used to make plastic dishes.

Strano and his colleagues found that under the right conditions, the monomer in melamine can grow tiny stacked two-dimensional discs, each of which is linked together by a hydrogen ring, making it extremely strong and stable. .

The material has a modulus of elasticity 4-6 times greater than that of bulletproof glass. Meanwhile, the force required to break the polymer (tensile strength) is twice as great as that of steel even though the density is only 1/6 of that of steel. Due to the ability to self-assemble, materials can be easily produced in large quantities by simply increasing the amount of starting material.

The new material, named 2DPA-1, can be used as a coating. Unlike other polymers that contain twisted monomer chains that create a gap for air to pass through, 2DPA-1's monomers bond as tightly together as LEGO bricks, giving the material a perfect waterproofing, providing protection. metal in cars and other vehicles or steel structures.

The team has applied for a patent for the process of making the new material. Now, they're looking at exactly how polymers form two-dimensional sheets to see if they could produce other useful new materials. They published the study on February 2 in the journal Nature.

- Israel made durable plastic such as steel

- Fabrication of new materials is lighter than aerogels, which is 10,000 times harder

- Application of cold-formed steel to build an earthquake resistant building

- New steel is 62 times more rigid

- Successfully fabricated 'hydrogel' fabric, five times stronger than steel

- Graphene: New materials can transform the world

- Resins can effectively block out cosmic rays

- Tips to clean stains and odors on plastic

- Create materials 200 times stronger than steel from cooking oil

- This is why fragile spider silk is 5 times stronger than steel

- New plastic resins like human

- Hard biodegradable yarn like steel made of wood cellulose

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste