Separation strips with ... polymer composite

Staff are installing two-way traffic signs with white and red signs For those who travel in Hanoi streets like Thanh Nien Street, Nghi Tam Street, 19-8 Square in front of the Opera House . It is easy to see the dividers here always keep the white-red colors stand out from the dividers commonly seen in Hanoi streets.

Staff are installing two-way traffic signs with white and red signs For those who travel in Hanoi streets like Thanh Nien Street, Nghi Tam Street, 19-8 Square in front of the Opera House . It is easy to see the dividers here always keep the white-red colors stand out from the dividers commonly seen in Hanoi streets.

But few will know that these are not familiar reinforced concrete blocks.

For the first time, products of composite polymer materials (PC) were present on Hanoi streets and also for the first time in Vietnam, not only making alternative dividers for reinforced concrete, PC also made protective guardrails, traffic signs .

This is a product from a research project of the group of authors of the Center for Polymer Materials Research (Hanoi University of Technology) has just won the third prize of Vietnam Science and Technology Innovation Award (VIFOTEC) 2005.

According to Dr. Bach Trong Phuc, chairman of the project, the use of popular reinforced concrete separators has many disadvantages: costly in the process of use because every six months it is necessary to paint once, dangerous Dangerous for users of vehicles, limited in terms of aesthetics, moving is complicated, heavy .

Dr. Phuc said that the products of separators, protective guardrails, traffic signs by PC at the same time ensure the requirements to overcome the disadvantages of the same type of reinforced concrete products: raising the level durable, capable of being affected by environmental factors such as humidity, temperature, ultraviolet rays to color fastness, impact of chemicals, fire resistance .

Scientists at the Polymer Research Center have also found that the optimal percentage of pigments blends meets the requirements of typical colors in traffic and is able to withstand weather.

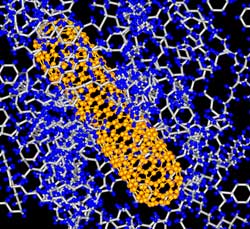

Especially carbon nanotubes - polymer composite model , the authors have successfully studied the use of some plant fibers (jute fiber, bamboo fear) as reinforcement to partially replace glass fiber. The project was evaluated as being innovative in the use of surfactants to increase the ability to disperse powder in plastic, improve material properties and cost.

Especially carbon nanotubes - polymer composite model , the authors have successfully studied the use of some plant fibers (jute fiber, bamboo fear) as reinforcement to partially replace glass fiber. The project was evaluated as being innovative in the use of surfactants to increase the ability to disperse powder in plastic, improve material properties and cost.

For the first time, by wet pressing technology, blocks of separators with hollow, sealed and glossy PC materials in three different colors on the same product have been put into use on some streets in Hanoi. Installation is easy with much lighter PC blocks than concrete.

After installation, just pump water or sand into the hollowed-out PC blocks to have a weight that meets the requirements for separators and guardrails. When you need to move, just open the valve, remove the water or sand . According to Dr. Phuc, due to the production of small-scale testing by manual methods, now the cost of the product with the high-density PC more than 1.5-2 times of concrete, protective guardrails and equivalent signs made of metal. If there are large-scale production processes, investment in synchronous machinery and equipment, the price will be much lower.

Economic efficiency is also because PC products are very light so the installation, maintenance and regular maintenance costs (paint, washing .) are very low compared to concrete and steel. Popular use in the street PC products also have high safety for people and vehicles to participate in traffic and give streets a higher aesthetic.

With the desire to have PC products widely used, the authors of the Center for Polymer Materials Research (Hanoi University of Technology) are willing to transfer technology for large-scale production by machine technology. Automation hook. Dr. Phuc estimated that with an investment of about VND 10 billion, a production line for separators or guardrails can be obtained by PC.

Currently, after Hanoi, Da Nang city has also begun to manufacture and install on roads and crossroads with PC.

Separation strip with red-white composite polymer

Post, photo: THANH HA

- Warning of early use of cancer detection strips

- Audi introduces lightweight lightweight composite material

- Thermal conductive polymer cools electronic devices

- Finding a new polymer can solve the plastic waste crisis

- Salt separation technology: Israeli

- How to use a pregnancy test

- Separation of antibiotics,

- Manufacture of new 6mm thick explosion-proof glass

- How to use a pregnancy test stick and how to read the most accurate pregnancy test results

- Aircraft made use of the composite finish first

- Self-biodegradable polymer materials

- Launched explosion proof composite gas tank

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water