Successful research on biomaterials stronger than spider silk

Scientists successfully simulated the process of tooth formation of a star star and applied it to create a durable, biodegradable, carbon-fibre material.

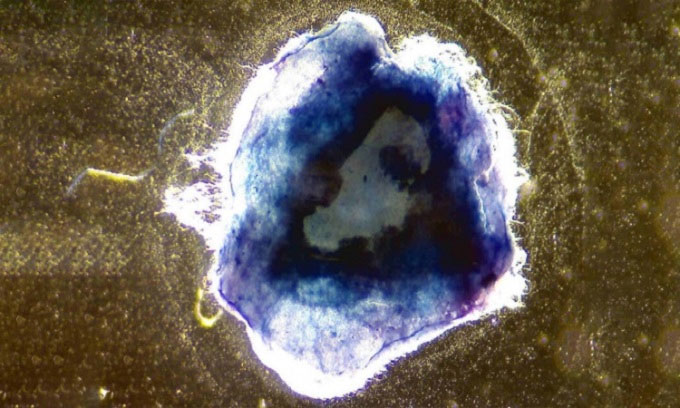

The stellar-inspired material is dyed blue in the lab. (Image: University of Portsmouth)

Research published July 7 in the journal Nature Communications shows that new biomaterials can be upgraded to become super-strong, comparable to the strength and flexibility of man-made materials, but without creating toxic waste. harmful. "Fully man-made materials like Kevlar are widely used, but the manufacturing process can be toxic, and recycling is also difficult and expensive. The materials we create here are much more sustainable in terms of source and manufacturing process, which is biodegradable at the end of its life cycle," said lead study author Robin Rumney from the University of Portsmouth's School of Pharmacy and Biomedical Sciences.

In 2015, researchers discovered the world's most durable biological material belonged to stellar stars, mollusks with conical shells that often cling to rocks. They use their tongue covered with microscopic teeth to scrape food off the rocks and put it in their mouths. These teeth contain a tough but equally flexible compound, much stronger than spider silk and comparable to man-made materials, including carbon fiber and Kevlar.

The extreme strength of star teeth is the result of a unique structure of chitin fibers, combined with fine crystals of goethite, an iron-containing mineral. These fibers intertwine in a similar way to the carbon fibers used to reinforce plastics.

To develop the material, the team developed a method to deposit chitin and iron oxide on serum coated glass, similar to the process in stellar teeth. After 2 weeks, the compounds themselves form a structure similar to a star's part called the blade, from which they develop into teeth. Rumney took 6 months to design the process.

After successfully simulating stellar tooth formation, the team was able to produce a 0.5-centimeter-wide sample of biomaterial by mineralizing chitin. Next, Rumney and colleagues will explore the possibility of increasing the size of these small plates and mass production, thereby replacing the use of plastic with a non-toxic biological product.

- This is why fragile spider silk is 5 times stronger than steel

- Spider silk - Biomaterial of the future

- Detection of spider silk formation mechanism

- Revealing the secret of spiders creating the world's most durable silk thread

- New generation artificial spider silk: more durable than steel and 98% made from water

- Found a way to transform genes to create spider silk like Spider Man

- New research: using spider silk will help treat fractures effectively

- Discover the mystery of spider silk

- Bulletproof vests will be made of spider silk

- Producing artificial spider silk lighter than cotton, more durable than steel

- Spider-Man's weapons are not logical about science

- Spider silk can transmit sound waves very well

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light