The method of making nanoparticles of hard magnetic materials is simple

US researchers have succeeded in making Sm-Co-based hard magnetic nanoparticles, an extremely important hard magnetic material in technology.

The team led by J. Ping Liu (University of Texas, USA) has achieved success from their feat by using simple high-energy dynamic ball grinding techniques in which particles are suspended in a surfactant. The particles are distributed in a relatively narrow area (high homogeneity), thus producing quite good antistatic force at room temperature.(You can see the results just published in the new issue of Nanootechnology ).

Rare-earth inter-metallic compounds - transition metals based on SmCo 5 and Sm 2 Co 17 components are very high crystalline anisotropic materials (reaching 20,106 J / cm 3 ) and therefore they have can give coercivity - an inverse magnetic field value for magnetization - extremely large. This is an important feature for the application. However, because they contain many rare earths (Sm), they are very susceptible to oxidation, this characteristic increases as the particle size decreases, which means that traditional methods of manufacture and methodologies are examples Typically, it is not appropriate to produce dispersed nanoparticles. Therefore, there has never been any research group that has succeeded in producing Sm-Co nanoparticles from hard magnetic properties at room temperature.

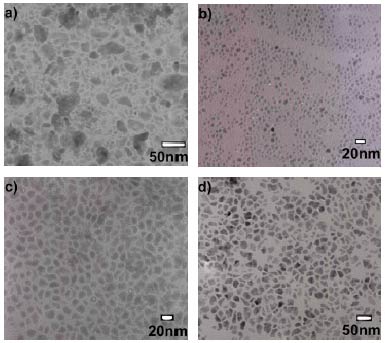

Figure 1. TEM image capturing Sm-Co nanoparticles in different grinding times.

"After confronting with the difficulties in making SmCo nanoparticles by chemical methods, we went straight to success in creating magnetic nanoparticles SmCo (cheap) - only by grinding particles from bulk materials with ball mill equipment " - Liu told Nanotechweb.org. Although ball milling is a very common technique in creating powder materials in metallurgy and ceramic industry, but usually only particles in micrometer sizes can be created even if crushed objects Data for a very long time. This is because the crushed grain can conjoin itself (" cold welding ") during grinding.

Liu and colleagues crossed the barrier by adding a surfactant to the mixture to help the fine particles suspended in the solution and not joined together . Another advantage is that surface activators help protect nanoparticles from external influences, such as contamination, oxidation, etc., which can destroy the magnetism of the object. material.

Figure 2. Room temperature hysteresis curve of nanoparticles (with different particle sizes).As the particle size increases, the coercivity decreases sharply (see small inserts inside).

The team also developed a technique to allow the selection of the generated particle size, in which relatively coarse particles ranging in size from 15 to 25 nm were selected. These particles exhibit hard magnetic properties at room temperature with magnetic resistance reaching 3 kOe."In fact, ball mill technology with the support of surfactants can expand to produce any kind of nanoparticle," Liu explained. Indeed, the team tried this technique with another important hard magnetic material, NdFeB. "These nanoparticles are capable of applying to nanostructured permanent magnets, magnetic media, magnetic fluids and biomedical treatment techniques - for example, medication or treatment. cancer by heating the local body temperature " - Liu said.

The results of the study have been published in Nanotechnolog magazine, and are currently studying the effect of heat treatment and covering the properties of nanoparticles to enhance the hard magnetic properties of the material system. this. "We are also working on compaction of nanoparticles using hot-pressing techniques to create a nanostructured SmCo block magnet," Liu added.

See more details of this group's work here .

The Doctrine of Independence

- By this method, two new types of magnets are found the fastest in history

- The magic of the first water-immiscible metal in the world

- Switzerland created the technology to kill potholes

- New materials help solve the mystery of the Earth's magnetic field

- How does the hard drive work?

- Hard biodegradable yarn like steel made of wood cellulose

- Fabrication of self-replicating materials

- Newly proven materials reach the limits of hardness, and are extremely light

- Super-hard metal helps build futuristic spacecraft

- Bone regeneration with magnetic nanoparticles

- All nanoparticles are magnetic?

- Inspired electronic butterfly material

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water