Turn discarded plastic bottles into chemical filters

In a world that seems to be engulfed in plastic bottles, recycling this waste into useful materials will reduce the impact on the environment. Researchers at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia have invented a way to turn plastic bottles into porous membranes that can be used as molecular filters in the chemical industry.

Bruno Pulido tests the effectiveness of synthetic films.

Approximately 40% of the chemical industry's energy is used to separate and refine chemicals in heat treatment processes, such as distillation and crystallization. The use of porous membranes to separate molecules from liquids can significantly reduce that energy consumption. But most conventional membranes are not strong enough to withstand industrial solvents, while replacement ceramic membranes are expensive.

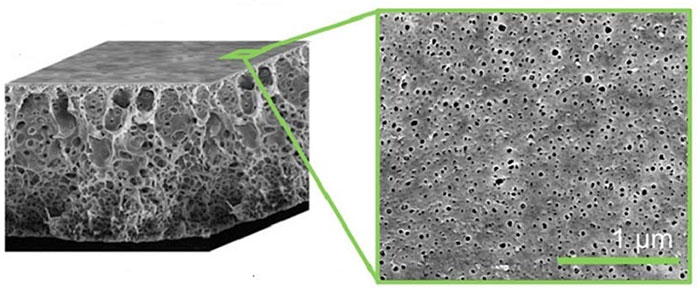

Electron microscope image of pores of a PET bottle (left) and filter membrane (right).

The KAUST team has turned to recycling PET plastic for making filters. ' PET is a powerful mechanical and chemical tool, useful for filtration and purification processes that require sterilization or cleaning with acids or bleaches , ' said Bruno Pulido, a PhD student, said.

In 2016, global plastic production reached 50 million tons, accounting for about 9% of total plastic production. About 30% of PET plastic is used in the food industry, including disposable plastic bottles. PET is often recycled into lower-value products, such as clothing fabrics, so converting it into a higher-value filter can provide a strong economic incentive to improve recycling rates. preparations.

To make the filter, the researchers dissolved the PET and then used the solvent to make a PET solid again, and this time the PET plastic took the shape of the filter, instead of the bottle shape.

The team tested a range of different treatment conditions and solvents and used poly (ethylene glycol - PEG) additives to help form pores in PET films. Changing the density and size of PEG molecules has helped to control the number and size of pores in the membrane, and thereby adjusting its filtration properties.

Fabrication of polymer composite films.

After optimizing this process, the team tested and the result was that fluids easily flowed through the membrane and they correctly separated different sized molecules. The best films have a pore size ranging from 35 to 100 nanometers, with pores accounting for up to 10% of the membrane's area; They also work well at 100 degrees Celsius.

Pulido believes that these membranes can be used as a support for thin layers of other filtering materials, such as those found in reverse osmosis membranes.'We are also working on developing hollow PET fibers, a type that has an advantage over flat films , ' he added.

Their research was published in the ACS Applied Polymer Materials, an electronic publication of the American Chemical Society.

- Plastic bottles - gold mines in Taiwan

- The habit of re-using plastic everyone does but brings unexpected harm

- A small 3D printing device that can help build houses with plastic bottles is easier than ever

- Don't inject plastic bottles to reuse many times, incalculable hazards

- Turn plastic bottles into arms and legs for the disabled

- Why is little beer packed in plastic bottles?

- Processing waste plastic bottles into phone cases

- The idea of water bottles made of jelly, decompose soon after use

- We are about to wear clothes made from plastic bottles

- Change plastic bottles to get bus and city tickets and clean and reduce traffic jams

- 2 secrets about plastic bottles of water that many people would wish for 'I'd rather not know'

- The scientist found a way to recycle plastic bottles into diesel

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste