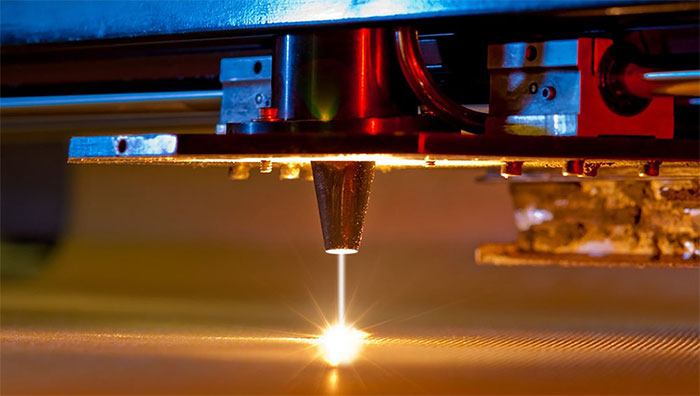

By super-fast laser, glass can be welded to aluminum, steel or titanium!

If using traditional heat welding technique, you cannot weld aluminum to steel, this technique requires two materials with the same characteristics. However, scientists at Heriot-Watt University have just announced a new welding method that can weld even glass to metals. Instead of thermal welding, they use super-fast lasers .

Welding glass and metals together is an important step forward in production and design flexibility.

"Being able to weld glass and metals together is an important step in product flexibility," said Duncan Hand, director of the development center for EPSRC laser manufacturing techniques at Heriot-Watt University. Currently, devices and products that use glass and metal can only be bonded together with glue, tape, and components over time, which will become loose and move. The chemicals in glues and tapes are gradually released and can affect product life. "

The new technique allows optical materials such as quartz, borosilicate glass and sapphire to be welded to materials such as aluminum, stainless steel and titanium. The development team used infrared lasers fired in series, each separated by a few picoseconds (1 millionth of a second).

Hand explained: "The two components are placed very close to each other, then the laser is focused through an optical material to create a very small focus point at the contact surface between the two materials to be welded together. The energy concentrated in an area of just a few microns has reached the megawatt, from which it creates a microplasma ray - like a microscopic lightning ball inside the material and this ball is enveloped, squeezed by an area. We tested this weld at a temperature of between - 50 degrees C to 90 degrees C and the results of the weld remained intact. We thought it was hard enough to withstand the conditions. extreme. "

Hand's team is currently working with experts to develop the prototype of the first laser welding machine, from which the technique could soon be commercialized.

- Aluminum 7075 can be welded, the future of cars and aircraft will be more durable and fuel efficient

- Detection of super-hard glass near steel

- 'Armor' for PC

- The laser produces super-fast currents, which can be used to adjust matter

- Reduce car weight thanks to new welding technology

- Use aluminum as a layer to cover the titanium surface to store hyrdo

- Glass is stiffer than steel

- New steel is 62 times more rigid

- Explain the chemical mechanism that makes stainless steel 'anti-rust' against the impact of the environment

- Made of gold aluminum, black platinum and green silver with a laser machine

- Turn red mud into steel

- How long ice tray nowhere?

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste