Inventing batteries can be surprisingly elastic

(Yonggang Huang) of Northwestern University and the University of Illinois' John A. Rogers was the first to invent a kind of scalable li-ion battery - a versatile device capable of providing Innovative electronic energy helps stretch.

Now there is no need to connect wires and electrical outlets anymore, stretched electronic components can be used anywhere, including inside the human body. Transplanted electronic components can track anything from brain waves to cardiovascular activity, which flat and rigid types of batteries cannot do.

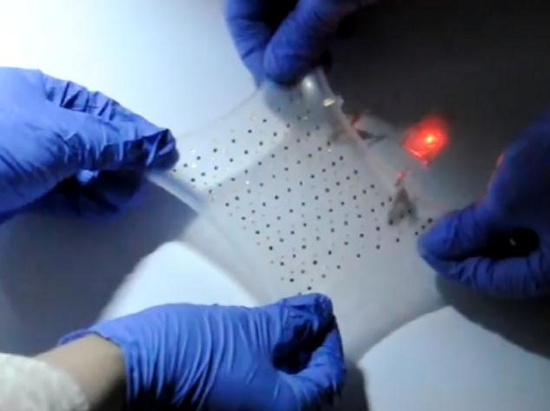

Huang and Rogers have invented a battery that continues to work to power a light-emitting diode (diode) lamp (LED) - even when stretched, folded, twisted and mounted on a elbow people. The battery can work 8-9 hours before needing to be charged for additional power, which can be done in wireless (wireless) form.

This new battery is capable of accurately integrating electronic and energy components into a small, flexible package. Details published February 26 by the Natural Media online magazine (Nature Communications).

"We started with a lot of battery components inside a very small space, and we connected them to tightly packed wavy wires ," said Huang, a co-author of the project. "These wires create flexibility. When we extend the battery, the wavy wires are spread out, just like we remove a coil of yarn," he said. And we can extend this device many times and still have an active battery. "

Elastic battery

Huang is in charge of research that focuses on theory, design and modeling. He is the main 'Joseph Cummings' , Professor of Civil Engineering and Environment and Engineering at Northwestern McCormick School of Engineering and Applied Science.

The power and voltage of the elastic battery will be similar to a conventional lithium-ion battery of the same size, but this versatile battery can last up to 300% of its original size while maintaining functionality. the same, similar.

Rogers is also a co-author of the project, in charge of the working group on testing and manufacturing elastic batteries. He is Swanlund President at the University of Illinois at Urbana-Champaign.

Huang and Rogers have been working together for the past six years on elastic electronic components, and designing a wireless power supply has become a big challenge. Now they have solved the problem with the smart intelligence of "space filling technology" , which helps create a high-charged battery.

For elastic electronic circuits, the two scientists have developed the "pop-up" technology that allows stretching and twisting of electronic circuits. They have created an array of small circuit elements connected by metal wires in the form of "penguin bridge" when the network is flattened, the wires - not hard and fixed electronic circuits - will be spread.

This approach is effective for electronic circuit boards but is not effective for elastic batteries. It takes a very large space for the above-mentioned linkage to work, but the battery's electronic components must be tightly packed and packed to produce a battery of high power but size. very small. There is not enough space between the electronic components of the battery so the "pop-up" technology works.

Huang's design solution is to use a series of metal wires, which are long wavy wires to fill small spaces between the battery's electronic components. (The current will run through the connections).

The only mechanism is a "coil spring in the spring" : the wire connects the large components of the battery with the "S" shape and in which "S" itself has a lot of small "S" . When the battery is stretched and stretched, the "S" will first extend and disappear, creating a small wavy wire. The extension continues with the disappearance of small wavy wires when the connection between the electrodes becomes strained.

"We call this sequential spinning , " Huang said. "And this is how we can produce an extended battery of up to 300% of its original size."

The prolonged process can be reversed, and the battery can be charged wirelessly. The battery's design allows for the integration of elasticity, induction coil to allow charging through an external source, but does not need to be physically connected.

Huang, Rogers and their team found that the rechargeable battery 20 cycles of charging has negligible capacity. The reporting system in this study includes a square array of 100 electrode plates connected in parallel.

- The brilliant inventions of mankind

- The latest 20 inventions about batteries change the technology in the future

- Video: 6-barrel machine gun made of elastic elastic wire

- Use 'elastic foam' to print artificial 3D hearts and more

- The person who has the ability to 'peel the skin' neck stuck on his face

- Energy breakthrough: Inventing the Solar battery works both in the rain and without sunshine

- 400 year history of battery formation and development

- Why does US aviation forbid to carry spare batteries in checked baggage?

- Turns the person's body energy into a battery

- The new battery works with ... saliva

- Breakthroughs help lithium-ion batteries last longer

- Discarded, dissolved in water for 30 minutes

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water