Massachusetts Institute of Technology engineers invent a paper-thin speaker

Engineers at the Massachusetts Institute of Technology (MIT) have developed a paper-thin speaker that can turn any surface into a sound source.

The new ultra-thin speaker model produces sound with minimal distortion while using much less power than conventional speakers. The palm-sized speaker that the team built weighs as little as a penny, but can deliver high-quality sound no matter what surface it is placed on. To achieve these advantages, the research team pioneered the application of a simple manufacturing technique that requires only 3 basic steps and can be scaled up to produce ultra-thin speakers with dimensions large enough to fit inside. car or stick in the room.

The new ultra-thin speaker can be manufactured at scale.

The new speaker model features active noise cancellation technology in noisy environments such as an airplane cockpit. This versatile device can also be used for entertainment by providing stereo sound in theaters or amusement parks. Because it is super light and requires very little electricity to operate, the speaker is suitable for application on smart devices with limited battery capacity. Vladimir Bulović, head of the Nanostructure and Organic Electronics Laboratory (ONE Lab) at MIT, and his colleagues published their findings April 26 in the journal IEEE Transactions of Industrial Electronics.

Conventional speakers in headphones or audio systems use an electric current flowing through a coil, producing a magnetic field that vibrates the diaphragm, creating the sound we hear. In contrast, the new loudspeaker simplifies the design by using a thin film made of piezoelectric material. This structure vibrates when an electric potential is applied, displacing the air above and producing sound. Most film loudspeakers are designed without support because the film must bend freely to produce sound. Placing the speaker on a surface will hinder vibrations and limit the ability to emit sound.

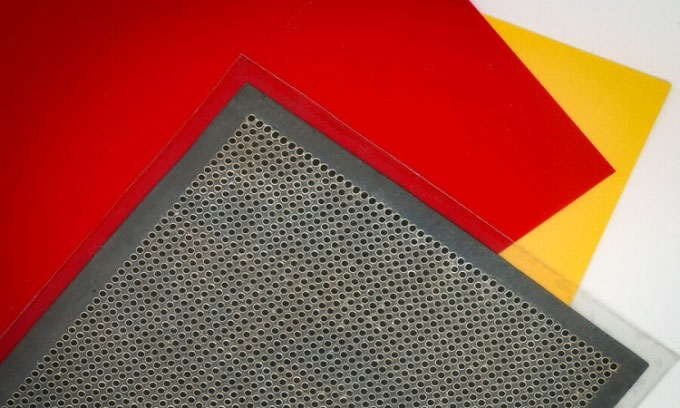

To fix the problem, the MIT team changed the speaker design. Instead of letting the entire material vibrate, they relied on tiny domes on a thin layer of piezoelectric material. Each arch as wide as several hairs can vibrate independently of each other. Surrounding those domes are paddings on the top and bottom of the film that protect them from the bonding surface but still allow them to vibrate freely. The padding also protects the dome from wear and tear in everyday use, enhancing the speaker's durability.

The domes are only 15 microns high, about 1/6th the thickness of a human hair, and move up/down 0.5 microns when vibrated. Each surround is an individual sound-producing unit, so it takes thousands of tiny surrounds that vibrate together to produce audible sound. Due to the vibrating domes instead of the entire film, the speaker has a high enough resonant frequency to be used effectively in ultrasonic photography. Ultrasound imaging uses very high frequency sound waves to produce images. The higher the frequency, the better the resolution of the captured image.

- The screen is as thin as paper

- MIT studies new transistors

- Invent for ink removal on paper for 5 minutes

- New paper antibacterial, waterproof

- As thin as paper, as steel

- The secret of the magic mine in waterbirds

- Manufacturing artificial spider silk: many useful applications in the future

- Successfully fabricated transparent, flexible speaker from gel ion

- Coming up with USB ... paper

- Swimsuits, dive-resistant, cold-drawn animals

- The TV can be rolled into a pocket

- Fabrication of new oil repellent

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water