New technology makes butanol - a better biofuel than ethanol

The team of researchers headed by an environmental engineer at Washington University in Louis is plying with new techniques to produce a biofuel better than ethanol called Butanol.

Derived from lignocellulosic materials, these are plant biomass parts that include woody stalks and straw to agricultural residues, corn fiber and rice husks, all of which contain a large amount of fiber and some wood. Butanol is considered to be a better biofuel than ethanol because it is less prone to wear and has a higher caloric value, so it provides higher energy values. Like ethanol, butanol is a substance to add to kerosene.

Dr. Lars Angenent - associate professor of chemical, environmental and energy engineering took processed corn fiber (a byproduct of corn ethanol production) from his collaborators at the Ministry. American Agriculture (USDA) at Peoria, III, and putting this lignocellulosic biomass into reducing machines involves cultivating a mixture of thousands of different bacteria to convert biomass into butirate.

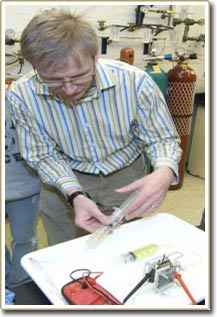

Lars Angenent, environmental engineer at Washington University in St.Louis in his Urbauer Hall laboratory.Angenent is an important member of the team using new techniques to produce butanol biofuels.(Photo: PhysOrg.com)

From there, the material is sent back to Peoria, where another collaborator, Dr. Nasib Qureshi, converts the butirate compound to butanol using enzymes.

US Department of Agriculture researchers Dr. Bruce Dien and Michael Cotta use chemical and physical techniques to make lignocellulosic materials difficult to decay , which is an important step. Enables mixed culture of Angenent to perform this modification.

He used a mixed culture containing thousands of different microorganisms and optimally evaluated the environmental conditions to select a microbial group to create an environment conducive to the transformation of corn fiber. butirate compounds.

Mixed culture techniques

Angenent said: 'My breakthrough in the laboratory is the use of mixed cultures. The benefit of mixed cultures is to simply take any material waste and convert it into valuable material through our operations. For example, I can change the pH in this culture. By maintaining it neutral, I could obtain methane, but when I lowered the pH, I could obtain the butirate compound. On the other hand, if I have a pure culture, I will not have to worry about other microorganisms that alter or pollute the environment. "

Lignocellulosic biomass is diverse, renewable, and an effective way to handle waste. By using it, we will open doors for better economic opportunities for crop producers and rural residents. Since this type of biomass is carbon neutral, we don't have to worry about carbon dioxide being released into the environment. '

In recent years, with the use of microbial energy cells and their mixed intermediate cultures, Angenent has created electricity or hydrogen in the process of wastewater treatment.

Together with the Agriculture Ministry's research collaborators, he was the key research investigator awarded by the US Department of Agriculture $ 425,000 for this study.

Butanol trends are increasing. In 2006, chemist Dupont and British oil company BP announced a partnership with British Sugar (British Sugar) to introduce butanol made from sugar beets made into kerosene in United England

- Find raw materials for Ethanol production plant

- Ethanol from sorghum - breakthrough biofuel

- Discover the unexpected use of beer

- Japan has the technology to produce cheap fuel from straw

- Major advances in biofuel technology: Garbage today, Ethanol tomorrow

- Making butanol from plants

- Turn E.coli bacteria into biofuel

- New breakthrough in artificial photosynthesis

- Turns the paper into 'gasoline'

- Beer brewing residues can be used to produce bio-gasoline

- Since 2009, Vietnam has started many biofuel projects

- New equipment turns breath into biofuel

Why do potatoes have eyes?

Why do potatoes have eyes? 'Tragedy' the world's largest carnivorous life: Death becomes ... public toilet

'Tragedy' the world's largest carnivorous life: Death becomes ... public toilet Tomatoes were once considered 'poisonous' for 200 years

Tomatoes were once considered 'poisonous' for 200 years Detecting microscopic parasites on human face

Detecting microscopic parasites on human face