Self-adhesive rubber made from waste

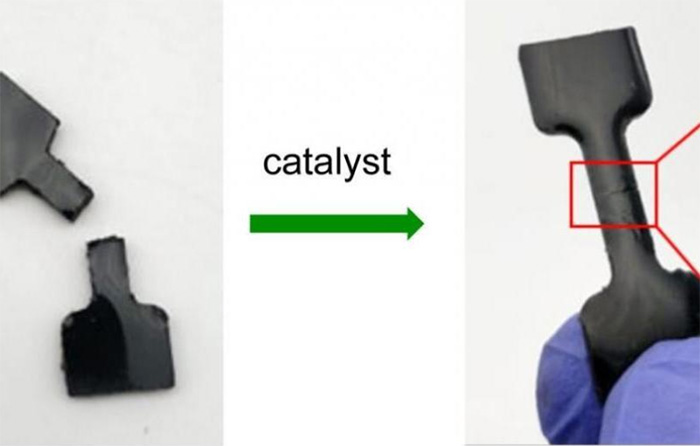

The researchers created rubber only from discarded materials, including sulfur, rapeseed oil and dicyclopentadiene from the refining process. When torn, the scientists activate the rubber to quickly heal itself at room temperature with an amino catalyst. In just a few minutes, the rubber was back as firmly as before.

This rubber material is fully recyclable, which can serve as a sustainable solution to many industrial and environmental problems, including used tires, which are clogged. clogging landfill sites across the globe.

This rubber can help reduce the carbon footprint of the tire industry.

The study shows a new concept in the field of sustainable rubber repair, bonding and recycling, lead researcher Justin Chalker, associate professor at Flinders University in Australia, commented in the newly released news. Father.

Because this new rubber - described in the journal Science Chemistry - is only made from waste materials, it can help reduce the carbon footprint of the tire industry. Currently, tires are made from crude steel, burlap and rubber, which requires significant amounts of energy and causes pollution.

According to scientists, this new rubber material can be used for many different applications, not just for tire production.

'It's interesting to see that the basic chemistry of these materials has such huge potential for recycling, next-generation adhesives, and additive manufacturing,' Chalker said.

The catalyst for self-healing rubber can also be used to create strong adhesives for industrial use.

Researcher Tom Hasell from the University of Liverpool said: 'The rubber binds to itself when the amino catalyst is applied to the surface. This adhesion is much stronger than commercial glue '.

This rubber is also resistant to water and corrosion. The researchers claim the polymer can be made in the form of bricks and fused together with an amino catalyst.

"In some cases, the amino catalyst makes the rubber bond in just a few minutes, and it can be done in heat , " said Sam Tonkin, a researcher at Flinders School and lead author of the study. room level. It can also be used as a potential binder, in that it binds to the surface of another piece of rubber when a catalyst is used. Basically, this rubber does not 'stick' until the catalyst is present.

- Ambition to clear ocean trash with rubber fence

- New products from waste rubber sources

- Manufacture of hydrophobic wood adhesives from waste sponges

- Turn rubber waste into cheap oil

- What does rubber molecule have to do with mass migration?

- How are waste from aircraft toilets handled?

- Successfully made a new adhesive.

- Flexible rubber keypad, programmable keypad

- Many children are sucking the poison into their mouths

- Japan develops a new plastic deformed like rubber

- Guayule - An easy-growing shrub for pure rubber latex to make tires of future vehicles

- Video: Stun with a full process 'hardship' to create a rubber band

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste