The process of molding the glass

Experts record 10 steps of the glass manufacturing process, in which the preparation and preparation of materials is quite complicated.

The first thing to do in the glass production process is to prepare silica sand material (quartz sand).The sand must be clean and free from iron, leaving the glass clearer, because the iron mixed in the sand makes the glass green.If sand cannot be found without iron, workers can adjust the glass's color effect by adding manganese dioxide.

The second step in the process is to add sodium carbonate (NANCO 3 ) and Calcium oxide (CaO) to the sand.Sodium carbonate (soda) lowers the temperature to the level needed to make glass.However, this makes glass water permeable.Therefore, calcium oxide or lime is added to overcome that disadvantage.Oxide in magnesium and or aluminum can also be added, making glass more durable.Typically, these additives account for a maximum of 26% to 30% of glass compounds.

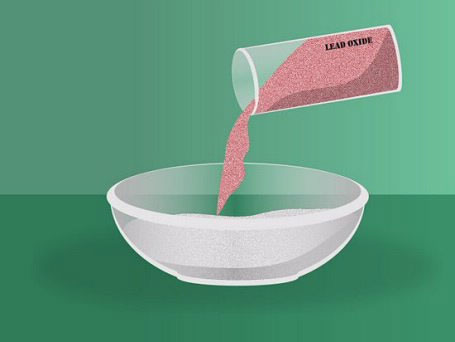

Next, other chemicals are added to improve glass properties according to the intended use.For decorative glass, the compound added is lead oxide, which sparkles crystal glass, while creating flexibility to easily cut and lower the melting temperature.For glass used for eyeglasses, users often add lanthanum oxide, as it is refractive and iron in this compound helps absorb heat.

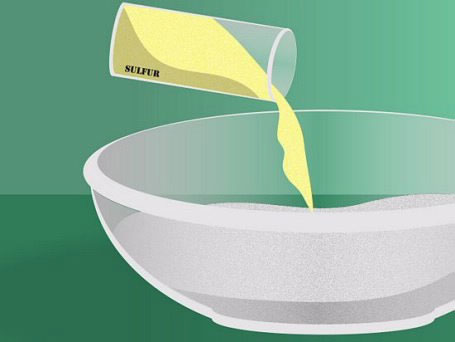

Colorants are added as desired.As mentioned above, iron humus in quartz sand makes glass green.Therefore, iron oxide or copper oxide is added to increase the greenness of the glass.The sulfur compound acts yellow, amber, light brown or even black, depending on the additional carbon or iron content.

Next, the mixture is poured into a crucible or a heat-resistant container.

Heated mixes melt to form liquid.To make quartz glass, the mixture is calcined in a gas furnace.For other special types of glass, workers need to use an electric furnace or an electric furnace.The firing temperature for no additive quartz sand is 2,300 degrees Celsius, for sand with added sodium carbon (soda) it is 1,500 degrees Celsius.

The mixture is homogenous and removes bubbles (foam bubbles) in the liquid glass mixture.The mixture is stirred to give uniform consistency, and to add chemicals such as sodium sulfate, sodium chloride or antimony oxide.

Melted glass is shaped in many ways. First, pour molten glass into the mold and let it cool. This is the Egyptian method, and the way to make lenses today.

Second, the molten glass is stacked on one end of the hollow tube, then it just turns the tube and blows it into the tube.Glass is shaped by air blowing into the tube, gravity pulls molten glass at the top of the pipe down to help shape.

Third, molten glass poured into melting tin containers to form a rack and blow compressed nitrogen glass to shape and polish.Glass made according to this method is called polished glass.This is how to make glass panels from the 1950s.

Before finishing, glass is cooled.

Glass is heated to enhance durability.This process is called tempering, which eliminates the point of condensation that can be generated during glass cooling.Once this process is complete, the glass is coated with an external coating, rolled or treated with other methods to enhance durability and toughness.

- How are the strengths produced?

- Technology to thin Microsoft's products that Apple needs to learn

- The new method increases the durability of glass

- What is glass?

- Unexpected uses of Gorilla Glass

- Smart glass

- New type of shockproof glass inspired by nature

- Discover 1,600-year-old glass furnace in Israel

- Glass has the ability to 'transform' when meeting water

- Car glass smashes in an emergency situation is more difficult than you think

- The process of molding chocolate from cocoa

- The reason we should classify glass junk

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?