The process of molding chocolate from cocoa

To create the chocolate, the manufacturer has to go through a lot of stages, starting with the harvesting and processing of the cocoa beans before being taken to the processing plant.

>>>Process of molding glass

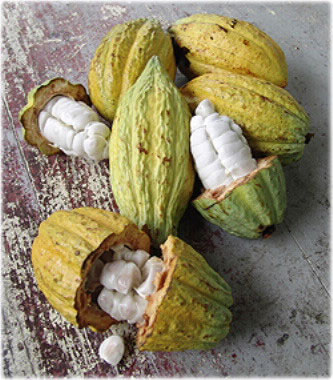

The first step is to harvest cocoa pods. Cocoa is a leafy green plant that grows in moist tropical lowland forests of Central and South America, West Africa and Southeast Asia. Cocoa beans grow in shells, sprout out of stems and branches. Their shells are about the size of a ball. The shell is green and turns orange when ripe. The harvester uses a milling cutter and gently cuts the cocoa from the trunk.

Next is the cocoa shell. Cocoa beans are selected and transported to processing plants to remove them from the shell. A cocoa pod can hold up to 50 cocoa beans. Cocoa beans are not brown and have no sweetness of chocolate as many people think.

Then there is the fermentation stage. Cocoa beans are placed on the surface of the heated tray, which is wide and shallow, then it is covered on a layer of banana leaves. If the weather is good, cocoa beans can be fermented under the sun. Fermentation is when the grain turns brown. This stage takes about 5 to 8 days.

The next stage is drying. After fermentation, cocoa beans must be dried before being put into sacks and transported to chocolate factories. The farmer only spread fermented cocoa beans on the tray and dried in the sun. This process usually takes about a week. When dried, seeds weigh only half of their original weight.

Roasting and screening stages of cocoa. First, cocoa beans are roasted to create colors and flavors suitable for consumers' taste. Seeds are fed into large drum roasting machines. Depending on the type of cocoa, roasted seeds at a temperature of 250 to 350 degrees Celsius for 30 minutes to two hours. After that, the seeds are removed to remove the outer shell. Cocoa pods can be sold as animal feed.

Next is the grinding stage of cocoa beans. After removing the crust, the beans are put into the crusher until it becomes a liquid mixture due to the amount of cocoa butter released from the kernel. Although it does not contain alcohol, this mixture is called 'cocoa liquor'. Cocoa wine is treated with alkaline solution, which helps the mixture not become dry again into powder. After that, cocoa liquor is mixed with cocoa butter and sugar. If it is milk chocolate, mix fresh milk and condensed milk or whole milk powder, depending on each manufacturer's recipe.

The penultimate phase is mixing cocoa liquor. Cocoa liquor continues to be mixed and processed so that after mixing milk and sugar, the mixture will achieve the desired smoothness. The basic recipe of milk chocolate includes sugar, milk or milk powder, cocoa powder, cocoa liquor, lexithin and white chocolate vanilla including sugar, milk or milk powder, cocoa liquor, cocoa butter, lexithin and vanilla. Pure dark chocolate includes cocoa powder, cocoa liquor, sugar, lexithin and vanilla.

Then the mixture continues to be mixed between the large steel rollers. The process of liquid mixture heated and continuously stirred is called 'conching' . High quality chocolate will take several days to experience the conching stage while low quality chocolate takes only a few hours.

- Chocolate can become a luxury item

- How to use cocoa correctly?

- Video: Journey to turn chocolate into a favorite dish

- Reduce cough with chocolate

- Eating chocolate makes you smarter

- Vitamin 'chocolate' helps prevent stroke

- Can chocolate be made from mango fruit?

- The more bitter the chocolate, the more anti-aging it helps

- Maya people use chocolate as spices

- Chocolate is going to be extinct? This technology may be the answer

- Chocolate milk: From specialty

- Vietnam owns the best chocolate in the world

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?