Ultra-light foam keeps indoor temperature 10 degrees cooler

The new type of foam made from nanofibers in wood promises to help reduce indoor temperatures sharply, while saving electricity consumed by cooling devices.

In a report published in the journal Nano Letters on May 5, the researchers designed an ultra-lightweight foam made of cellulose nanocrystals taken from wood, which can reflect sunlight, emitting absorbed heat. and insulation. According to them, this material can reduce more than a third of the energy need to cool the building.

The cooling foam material is derived from wood.

Although scientists have developed many cooling materials, they still have many disadvantages. Some materials release a lot of heat absorbed through the building in direct midday Sun during the summer months. Other materials are not effective in hot, humid or cloudy weather. So, the team from Nanning Forestry University, aimed to develop a material that can reflect sunlight, release passive heat and prevent heat from passing through the building.

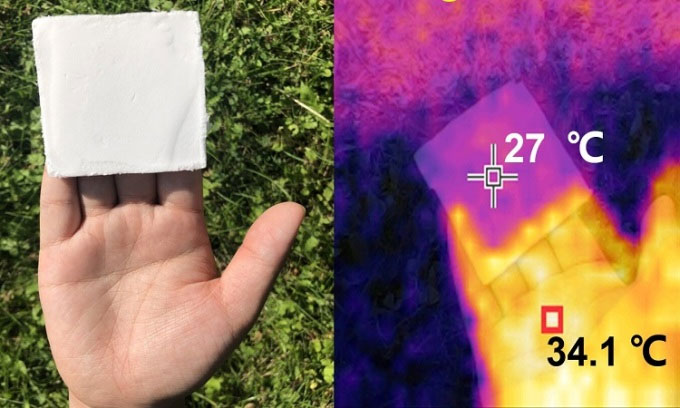

To produce the cooling material, the researchers bonded cellulose nanocrystals together with a bridge made of a silane compound before freezing and sublimating the material in a vacuum chamber. This process causes the nanocrystals to align vertically, creating an ultralight foam that reflects 96% of visible light and emits 92% of the absorbed infrared radiation.

When coated on top of a foil-lined box placed outdoors at noon, the material helps to keep the temperature inside the box 9.2 degrees Celsius lower than the outside temperature. Moreover, the material also maintains a temperature inside the box which is 7.4 degrees Celsius cooler than outside in wet conditions. When foam made from cellulose has been tightly pressed, its cooling capacity is reduced, revealing a variety of adjustable properties.

The team calculated that if cooling foam was placed on the roof and outside walls of a building, the energy demand for cooling would be reduced by an average of 36.4%. The performance of wood-based cellulose foam can be adjusted according to weather conditions. The technology can be applied in a variety of environments, the researchers say.

- 'Air conditioner' invention does not need electricity for summer day 45 degrees Celsius

- Strangely, the boy has a temperature of 30 degrees

- Japan: The indoor farm is 100 times more productive than the field

- Mysterious foam fire of veteran missiles

- The two countries have terrible temperature differences: nearly 100 degrees Celsius

- Shocking research: The smartest person at 22 degrees Celsius

- August temperature is the fourth highest in history

- 'Superman' tape: Lighter than paper, lifting even concrete

- What is saliva urine? How to treat?

- Styrofoam boxes should not be used at temperatures higher than 70 degrees Celsius

- You used to cold 22 degrees Celsius

- Solar cells are as light as soap bubbles

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light