Classification of nuclear reactors

There are many ways to classify nuclear reactors, of which the most common classification is based on the retardants and heat transfer agents used in the reactor.

How many types of nuclear reactors?

Nuclear reactors are a device for starting, controlling, and maintaining a chain of nuclear reactions. Nuclear reactors are often used to generate electricity and provide energy by using heat from nuclear reactions to spin steam turbines.

Nuclear reactors are classified according to several methods as follows:

- Classification by purpose of use.

- Sorting by substance slows.

- Classification by neutron energy.

- Sort by capacity.

- Sorting by furnace generation.

- Sort by type of nuclear reaction.

- Classification by regulators.

- Sort by coolant.

- Sort by rank.

- Classification by purpose of use.

Here is the most common classification, based on the retardants and heat transfer agents used in the reactor:

Water - water reactor

Fuel rods are placed in boxes placed in the reaction area. Water is both a heat transfer agent and a slowing agent. Water as a heat transfer agent is introduced into the reactor, running along the reaction area from bottom to top. Pressure in water - water reactor is about 1-2MPa.

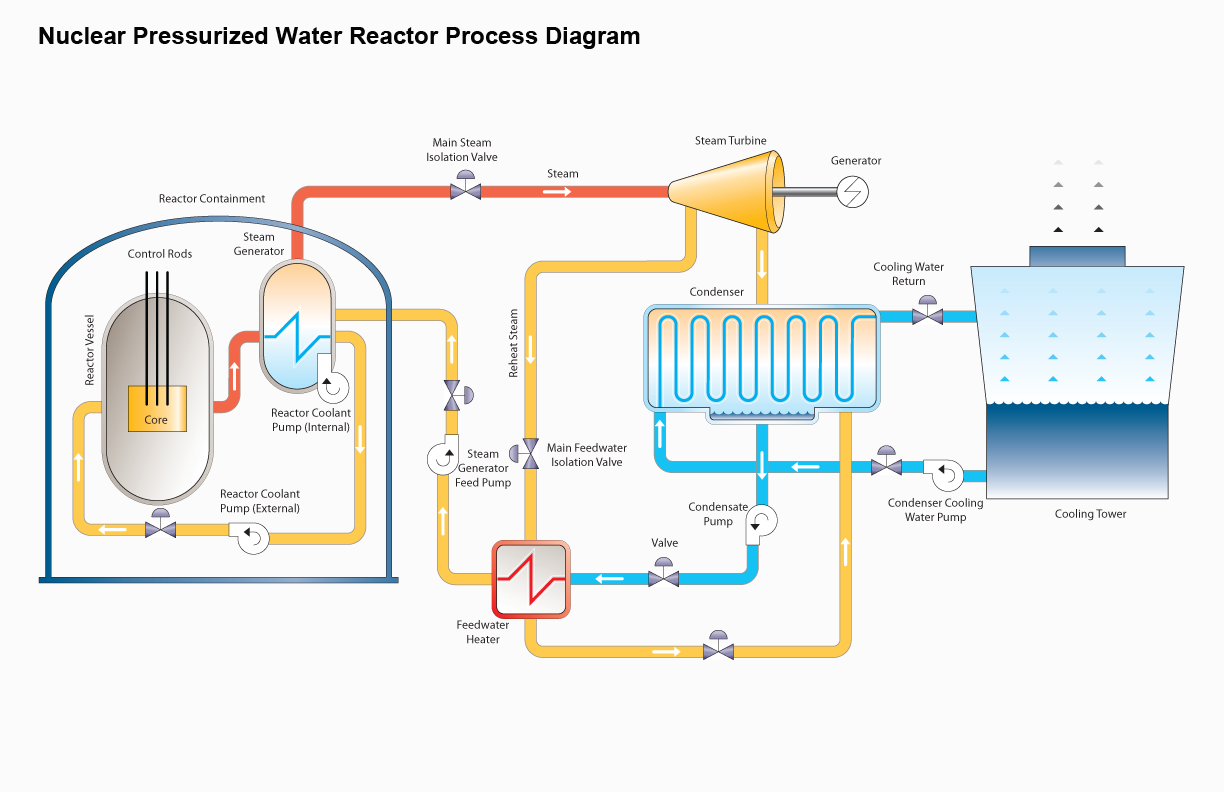

Indirect steam-forming water furnace: Primary ring thermal load, kept in a liquid state under high pressure, brings heat from the nuclear furnace to a steam generator, where heat exchange occurs with the secondary ring. and steam generated and lead to turbines.

Boil steam steam directly by boiling the heat load in the oven. The vapor is separated from the liquid in a separating device placed above the operating area, then sent to the turbine.

Improved diagram of boiling water furnace

Graphite reactor

Graphite is used as a retardant, a heat transfer agent in a graphite reactor that can be light water, heavy water, gas, or molten metal.

Fuel rods are placed in pipes and heat transfer materials. Surrounding pipes is graphite. At high temperatures, graphite reacts with air, so the retarder of graphite is placed in sealed metal containers. Bioprotective layer is made of thick concrete, helium inert gas or CO2 pumped into the reactor.

Structure of graphite reactor - РБМК -1000 : Reaction zone (activity), steam pipe, steam separator, main pump, electric commutator, water pipe as heat transfer agent, biological protection class Above, furnace start system, biological protection layer below.

Reactor using neutron activates large energy (fast neutron)

Raw materials used in the kilns are enriched U235 and Pu239 (15%). Transmission line reactions occur under the activation action of fast neutrons. Surrounding the reaction area is the U238 or Th232 sheet, which is responsible for absorbing all the fast neutrons, also known as material regeneration zones. The plate U238 and Th232 when the neutron absorption will become Pu239, U233, it will detach during the recycling process.

In fast reactors using neutrons, there is no need to use neutron retardants. Liquid metal (Na, K, or Na - K mixture) is used as a heat transfer agent.

The fast neutron reactor activates without slowing agents , using enriched material bars, and arranges close to each other, so the heat output is very large (1000 kW / l), so the capacity of This type of reactor is big. The heat transfer agent must be capable of rapid heat exchange, commonly used as liquid metal (Na, K, or Na - K mixture) used as a heat transfer agent. Also due to the use of raw materials is the uranium bars are enriched so the safety level is also lower than other types of furnace.

Reactors use high-energy neutrons

High-temperature furnaces load heat with gas heat, with graphite as a retardant

This type of furnace has not been commercially operated, is an alternative to conventional design. It uses graphite as a retardant and helium gas is a heat load. The outstanding feature of HTGR is its high safety . Their fuel is encased in a ceramic shell that can withstand temperatures above 1,600 degrees Celsius while the effective working temperature of the furnace is 95 degrees C. Helium is directed to the turbine.

Types of nuclear reactors are commonly used in the world

Today, the technology of nuclear reactor development is very rich and diverse. There are more than 10 types of kilns being used, research and development.

Light water furnace: (including boiling water furnace - BWR and pressure water boiler - PWR): plays a key role, accounting for a large proportion in many countries with nuclear power. This is a technology that has not only been developed, perfected and commercialized widely in the world but is also a potential technology for strong improvements in the near future. Large-capacity light water kilns are being upgraded to improved reactors with greater capacity.

Pressure reactor, use light water as heat transfer agent

Heavy water furnace: Starting to grow from Canada, so far this kiln technology has been applied in many countries, especially some countries have started developing nuclear technology from heavy water like China and India. It is important to develop heavy water kilns and have autonomy in this technology. Most recently, Romania has entered this technology and built two units. Heavy-duty water furnaces have a flexible fuel cycle that can use natural uranium, low-enriched uranium reconstituted from PWR's recycled fuel, mixed oxide fuel, thorium.

High-temperature gas furnace: Developed in the United States, England and West Germany, this furnace uses graphite to slow down neutrons, helium as a heat and fuel load, and a high-enriched uranium-thorium tablet surrounded by graphite. However, the current gas kiln technology seems to stall. The research and development directions focus on high temperature gas furnace, round pellet fuel-type furnace with Graphite cover. A great possibility for the application of gas furnaces is to produce hydrogen for fuel cells.

Fast neuron: Using high-enriched uranium or plutonium as fuel, the active zone is surrounded by natural uranium and liquid metal used as heat load. The unit uses a fast neutron furnace with 3 cycles, round 1 through the active zone, round 2 through the middle and round 3 is the cycle of the bio-substance, through the turbine.

Furnace system using accelerators: A recent development is to combine fission furnace technology and accelerator to generate electricity and metabolize long-lived isotopes in radioactive waste. High-energy proton beams hit heavy metal beer to produce neutrons.

Names and symbols of common reactors in the world

- ABWR - Improved boiling water furnace

- AGR - Improved furnace, using graphite as a slowing agent, gas as a heat transfer agent.

- BWR - Boiling water

- FBR - Reactor uses high-energy neutron (fast neutron)

- GCR - Reactor uses graphite as a slowing agent, gas as a heat transfer agent.

- HTGR - High temperature furnace, gas thermal load, with graphite as a slowing agent.

- HWGCR - Heavy water reactor as a slowener, gas as a heat transfer agent.

- HWLWR - A light water reactor as a heat transfer agent, heavy water as a slowing agent.

- РБМК - The reactor uses graphite as a slow, light water to conduct heat.

- PHWR - Pressure reactor, using heavy water as a heat conductor and slows down

- PWR - Pressure reactor, using light water as a heat transfer agent.

- SGHWR - Heavy water reactor as heat transfer agent

- ВВЭР - Water-water reactor (Russian style, equivalent to PWR furnace)

- Space nuclear reactors help to colonize Mars

- Nuclear reactors supply electricity to Martian settlers

- Prospects for small nuclear reactors

- Prehistoric nuclear reactors

- Japan discovered a fire risk in many nuclear reactors

- Vietnam prioritizes nuclear safety

- Research and development of new generation advanced nuclear reactors

- China prepares to export nuclear reactors

- Japan develops nuclear reactors for export

- Russia manufactures electricity and desalination reactors

- Smoke, steam rising from 2 Japanese reactors

- Learn about nuclear power technology

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?