Create an ultra-thin power generation system that uses glucose in the body to produce energy

Our bodies absorb glucose from food, taking energy to run every cell inside. Given its nature as an energy source, could glucose become the 'life force' for implantable medical devices?

Engineers from the Massachusetts Institute of Technology (MIT) and the University of Technology Munich acknowledge this potential, and have designed a glucose energy cell that can convert sugar in the body directly into energy. The device is smaller than previously announced models, only 400 nanometers thick (about 1/100th the size of a human hair).

The sugar-based power source generates about 43 microwatts per square centimeter of device area, setting the record for the highest energy density ever. Notably, the device works in normal conditions.

Another thing worth mentioning, the devices are durable and can withstand temperatures up to 600 degrees Celsius. They can 'survive' the implantation process, which involves high-temperature sterilization.

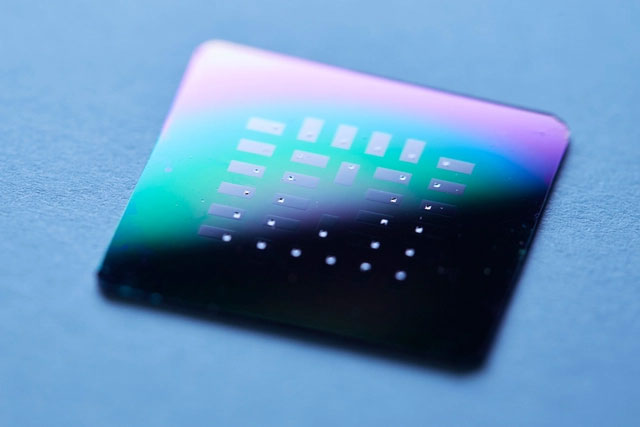

Silicon chip with 30 glucose energy cells - are small cavities located inside the chip.

The heart of modern devices is made of ceramic, a material that continues to assert itself in the technology industry. The researchers envision a bright future where energy cells can be laminated into a film, or wrapped around an implant. It will absorb the abundant glucose in the body to power the device.

"Glucose exists everywhere in the body, the idea here is to harness the available energy to operate electronic devices," said Philipp Simons, designer of the new device. 'Our test demonstrates a glucose energy cell using new electrochemical technology'.

Renowned professor Jennifer LM Rupp, who is also the project supervisor, said: 'Instead of using batteries, which take up 90% of the implant's volume, you can create a device as thin as a film, does not take up much equipment space'.

The size of a common pacemaker.

The multinational research group was not the first to consider glucose as an energy source for electronic devices, as the brilliant minds of the 1960s thought about the potential of sugar in the body. But the breakthrough technology has been hidden under the shadow of lithium-iodide batteries for many years, unable to become the source of electricity for implanted devices, such as pacemakers.

However, lithium-iodide battery technology, or similar to today's mass battery technologies, possesses a major weakness. Batteries need to have a large volume to be able to store energy.

'Our energy cells convert energy, not store it,' Professor Rupp said of the potential for space saving for future devices. In recent years, energy cell technology using glucose is being mentioned more and more by research institutions.

Device construction

The basic design of a glucose-powered energy cell consists of three layers: two terminals, with an electrolyte in the middle. The upper anode reacts with the glucose present in body fluids, converting the sugar into gluconic acid. Metabolism releases a pair of protons and an electron pair. The electrolyte acts as a barrier between protons and electrons, allowing electrons to flow freely into an electrical circuit, where it exhibits its ability to provide energy.

The electrolyte also acts as a bridge for the proton to move through the energy cell, allowing the proton to combine with air and create a harmless water by-product.

Research equipment used to activate energy cells.

The middle electrolyte is made from ceria, a highly ion-conducting ceramic material that is flexible in shape, and is still widely used in the production of hydrogen energy cells. Studies show that ceria is also biocompatible.

'Ceria is deeply researched in the anti-cancer community,' says Mr Simons. "It has many similarities with zirconia, which is used in dental implants, and also has a high degree of safety and compatibility with biomaterials."

In testing, many of the power cells reached a voltage of 80 millivolts, the highest energy density of any glucose battery model ever. According to Mr. Simons, the team generated enough energy for an electric current to drive the implant.

'They've opened up a new avenue in making tiny electrical sources, for implantable devices and other functions,' said Truls Norby, a chemistry professor at the University of Oslo, who was not involved. New research, said. 'The ceramic used is non-toxic, low production cost, adaptable to both body conditions and sterilization process. The concept and the prototype device obtained are very promising'.

- New invention of ultra-thin insulation

- The amazing diamond revolution in Russia

- Solar cells that are thinner than hair will soon appear everywhere

- Successfully developed ultra-thin electronics

- The device is about to be thin

- Ultra-thin solar cell system, can be attached to all surfaces with tape only

- When should I put glucose into my body?

- Denmark set a new world record for wind energy

- Scientists seek to create ultra-thin keyboards that absorb light

- Sony successfully developed ultra-thin screens that can bend

- Can your body's motion generate electrical energy?

- The first wave-producing model of electricity from the sea

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste