Development of 3D printing ink from living bacteria

3D printing ink is made entirely of E. coli bacteria, helping to create sustainable constructions that can repair themselves.

American scientists have created a live squid made entirely of bacteria. This bacterial ink melts like toothpaste under high pressure and can be 3D printed in a variety of shapes, including circles, squares and cones. All can keep their shape and sparkle.

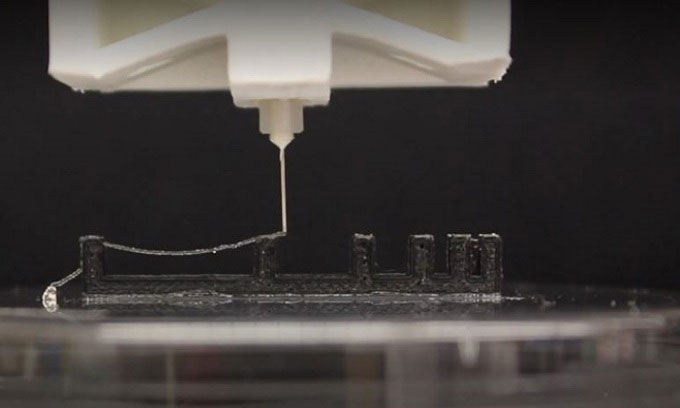

Experiment with placing ink filaments on small columns.

The team describes the bacteria-laden 3D printing inks in a paper published November 23 in the journal Nature Communications. The new ink is still in development but holds promise as an important renewable building material that can mend itself and is ideal for building sustainable homes on Earth and in space.

In the past, scientists have created many printed gels that are a combination of bacteria and polymers. One of them contains hyaluronic acid, seaweed extract, and smoked silica, which make the material thicker and more viscous. But the new material does not contain polymers, but is produced entirely from genetically modified E. coli bacteria. The team used a culture medium made of live bacterial cells for the ink to grow. When harvested from liquid cultures, the ink becomes jelly-like, which can be fed into a 3D printer to print living structures. Structures do not grow any further and retain the printed shape.

Bacteria are important ingredients in many products such as perfumes and vitamins. Researchers have engineered bacteria to produce biodegradable plastic. According to Neel Joshi, a synthetic biologist at Northeastern University and a co-author of the study, bacterial ink is central to the field of genetically modified marine materials. Unlike structures made of concrete or plastic, living systems automatically adjust to the environment and are regenerative.

Normally, bacterial ink relies on a polymer skeleton to harden. But polymers have their own limitations and can change the mechanical properties of the ink unintentionally. In addition, the polymer must be biocompatible so that the bacteria do not die. Synthetic polymers such as polyethylene are usually oil-based and are not renewable.

Many genetically engineered living materials come in the form of hydrogels, structures that can absorb large amounts of water. In 2018, Joshi and Anna Duraj-Thatte, an engineer at the Virginia Institute of Technology, successfully created a hydrogel entirely from E. coli with the ability to grow and reproduce. Although this hydrogel can be passed through a cylinder, it is not strong enough to support its own weight, and therefore cannot form any structure.

The team needed to harden the material. They genetically engineered the bacterium E. coli to produce a protein polymer from fibrin, designed to bind into a lattice-like network. This change causes the material to harden enough for printing, while still being able to flow from the 3D printer's nozzle. The researchers brought 3D printing ink to the lab of Yu Shrike Zhang, a bioengineer at Harvard Medical School.

There, they printed the bacterial ink in a variety of patterns and patterns to test its ability to maintain its shape. The ink flows like toothpaste from the printer but does not melt after printing and passes all tests. They also looked at how much the ink fibers could stretch without breaking. In the test, the printer's nozzle ejected a half-millimeter thick filament of ink through a row of columns spaced apart. As a result, the ink filament can support its own weight between columns, spaced 156 mm apart.

Bacterial ink still needs to grow because it is prone to drying out and is not stable enough to build larger structures such as human dwellings. Researchers are looking for ways to make 3D printed structures more solid. However, they stress the future application potential of this ink is limitless.

- Studying bacteria using 3D printing technology

- 'Live tattoo' can glow to warn pollution

- The most toxic and strange forms of bacteria on the planet

- Technology of printing cells of woodblock prints with the survival rate of nearly 100%

- Bacteria, an inevitable part of ... humanity

- Build your house using 3D printing technology without using brick

- Project Escher: Autodesk Multi-Dimensional 3D Printing Development Project

- Detecting bacteria resistant to living conditions on Mars

- Detects big security flaws in 3D printing technology

- Find the key of immortality from bacteria living 3.5 million years ago

- How do insects 'tame' the bacteria?

- 'Living antibiotics' from bacteria

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste Secrets of confidential ink, stealth ink

Secrets of confidential ink, stealth ink  Invent for ink removal on paper for 5 minutes

Invent for ink removal on paper for 5 minutes  These images will make you think again before you want to go tattooing

These images will make you think again before you want to go tattooing  Ways to create a stealth letter from the most basic items

Ways to create a stealth letter from the most basic items  Chemical components of blue ballpoint pen ink

Chemical components of blue ballpoint pen ink  What is the blue part of the eraser used for?

What is the blue part of the eraser used for?