Invented a new super elastic alloy

Japanese scientists have successfully developed a new super-elastic alloy. This material can be used in high-rise buildings to reduce impact when an earthquake occurs.

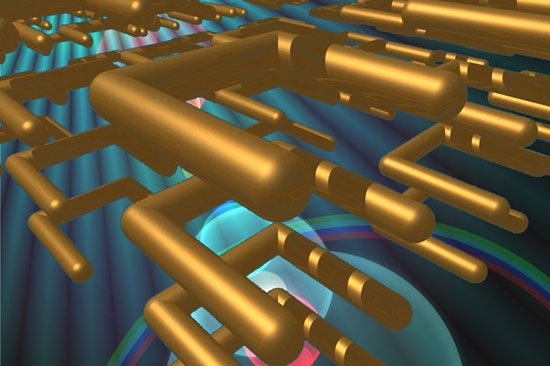

Image for illustrative purposes

Reuters news agency reported that scientists from Tohoku University (Japan) have added a small amount of nickel into iron alloy to create a super-elastic alloy. This new material can restore the original shape after being heated at a temperature of 196 - 240 degrees Celsius.

According to Dr. Toshihiro Omori, the head of the research, the new material has much better elasticity than the previous super-elastic alloys, which cannot recover the original shape after being subjected to lower temperatures - 20 degrees C or over 80 degrees C.

'Our super-elastic alloy material is very sensitive to temperature. This is a very important characteristic for a material when temperature changes. Another advantage of this new material is its low cost. Therefore, it can be used for large applications , 'said Dr. Toshihiro Omori.

The new super-elastic alloy can be used in environments with large temperature fluctuations such as axles or joysticks in cars, aircraft, spacecraft, . In addition, it also can be used to reduce vibrations for tall buildings when an earthquake occurs.

Asia is a leading region in the field of materials science research, especially China. About 1.1 million research projects related to materials science have been published every year by Asian scientists in recent years. Meanwhile, scientists from the US have only 38,189 research works on materials science published annually.

- New alloy super durable, corrosion resistant

- The person who has the ability to 'peel the skin' neck stuck on his face

- Alloys 'transformed' 10 million types

- Develop super-elastic gel, remove the wound from peeling

- Use highly elastic biological materials to regenerate bone

- Video: 6-barrel machine gun made of elastic elastic wire

- Grace - Super bike electric

- 'Super elastic' material changes shape according to temperature

- Create a super-elastic material that can generate electricity when pulled or compressed

- Use 'elastic foam' to print artificial 3D hearts and more

- Japan invented 'super glue' used underwater

- Elastic cord made of material more durable than steel 200 times

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water