Learn about 3D printing technology

About 40 years ago, those who heard the sound of the radio for the first time, saw their picture on a piece of paper, or saw little people running around in a square square box, was something can imagine.

Today, science and technology is booming, wherever we are, we can hear all the 3D TVs, 3D movies, 3D sounds, 3D images. All of these terms refer to technologies that create a psychedelic illusion on human vision and hearing, to simulate what we can see and hear.

3D simulated TV.

But 3D in 3D printing technology is a completely different definition from simulated 3D that we mentioned above. 3D here is the real product, the real object that we can hold in our hands, touch and observe accurately, 3D here is everything around us, but from the very beginning to the present we still contact everyday, too familiar and we don't call it 3D.

Example: You are using your laptop, and the laptop is the 3D object we're talking about here. That is to say, so that we can clearly distinguish 3D printing here is to print out a 3D object that can be touched, observed, grasped, not printed out an image but we look at it floating 3-dimensional is almost like real life.

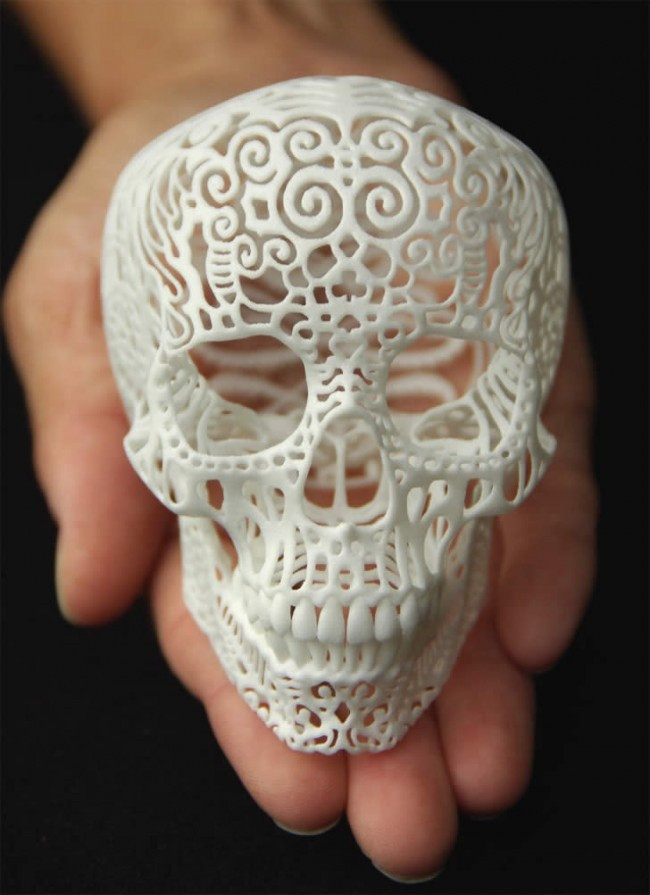

A product from 3D technology.

In the above distinction we understand the Product from 3D printing technology is to print out a 3D object that we can touch, observe and grasp. But to make or create a 3D object, there are so many ways, from traditional to modern, and why it is printed.

What is 3D printing? How does the 3D printer create rapid prototypes?

It is easy to imagine that we imagine the following: Perhaps everyone has heard about CT scans, the CT machine has the task of taking each cut layer from the neck up to the top of our head (if we have a first tomography) When we look at the CT film, we see a lot of cross-sectional images with outer rings that are the skull bones, inside the sliced shapes of the brain and organs.

CT scan film.

If we suppose we put each of these sliced CT images in paper and then stack them up on each other, one sheet after another in each order. Assume that the ink on the upper sheet of paper adheres to the ink on the paper sheet below. Now we will get a rectangular box of paper, then we remove all the excess white paper. Now we will get a 3D ink cartridge whose shape is our head, and it has all the parts from inside and outside.

So 3D printing is to print the content (CT cut image above) on each layer (the paper above), the layers are printed in succession, overlapping each other, layer by layer. The main ink is the material you want to apply to 3D objects, be it plastic, paper, powder, polymer, or metal, . These materials are characterized by having a bond to each other to the layer material. The above is attached to the underlying layer.

Today due to its popularity and ease of visualization, it is called 3D printing, in fact, in industry people call 3D printing as rapid prototyping. Called rapid prototyping because compared to other methods of fabricating 3D objects (samples) such as cutting, cutting, turning, milling, planing, molding, . this method allows for faster sample creation.

What is 3D printing technology?

3D printing technology or rapid prototyping technology is a way to perform 3D printing, or a way for 3D printers to work. Today 3D printing technology develops very diverse, with each 3D product can be printed with a variety of different materials, bulk materials, liquid, powdered dust. For each type of material, there are many ways to print such as using laser, cutting tools, plastic extrusion, . How to print, it is printed from the bottom up, printed from the top down.

3D printing technology with nano size.

3D printing technology trend of the future?

What are the 3D printing technologies that make the experts assess that this is a strong development trend in the future, the trend of the future?

A product from 3D technology.

- The first advantage is as its name suggests: Rapid prototyping technology, this technology has the superiority of time to manufacture a finished product. 'Quick' here is just a relative limit. Usually, it takes about 3 - 72 hours to create a new product, depending on the size and complexity of the product. You might think that this time seems slow, but compared to the time that traditional manufacturing technologies often take from weeks to months to create a product, it is much faster. Because it takes less time to create products, manufacturing companies save costs, quickly bring new products to market.

- Second special advantage: As in the 3D printing example above, we can build a human head with all the internal and external parts in detail in just one execution. but traditional methods cannot be built.

- Magic 3D printing technology

- Build your house using 3D printing technology without using brick

- Build a cluster of houses with the world's first 3D printing technology in the Netherlands

- Technology of printing cells of woodblock prints with the survival rate of nearly 100%

- Diversified 3D printing materials

- Unbelievable applications of 3D printing technology

- Uses 3D printing technology to create steel structures

- 3D printing gets both corneas and implants successfully, people really come to the future

- Recreate parts of the body with 3D printing technology

- Detects big security flaws in 3D printing technology

- Israel develops meat products with 3D printing technology

- The first pharmaceutical to use licensed 3D printing technology in the United States

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?