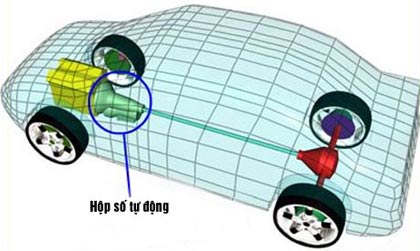

Operation principle of automatic transmission

How does the automatic transmission work? If you've ever driven an automatic car, you'll definitely notice two distinct differences between an automatic vehicle and a manual-operated car.

The difference between automatic transmission and manual transmission

On the automatic transmission, you will not find the clutch pedal and there is no need to shift the gear (1, 2, 3, 4 .). The only thing you need to do is to put the number in the D (drive) slot, then everything is automatic.

Both automatic transmission (with torque converter) and mechanical gearbox (with dry friction clutch) have the same function, but the working principle is completely different. And if we look deeply, we will see that the gearbox automatically does amazing things.

In this article, we learn about automatic transmissions. We will start with the bottom line of the entire system: planetary gear sets. Then we see how the details of the gearbox are assembled, how they work and finally discuss some of the complex issues related to automatic transmission control.

Just like a mechanical gearbox, the main task of an automatic transmission is to allow the reception of the engine power at a certain speed range but provide the greater speed range at the output.

The gearbox uses gears to take advantage of the torque effect of the engine and helps the engine provide the most appropriate speed zone wheels according to the load modes and the operator's wishes.

The main difference between the automatic gearbox and the mechanical gearbox is that the gearbox changes the fitting of the cogwheels to create different gear ratios between the primary axis (connected to the engine). and secondary axis (connected to the shaft that transmits active bridges). While the automatic transmission is different, planetary gear sets will perform all of these complicated tasks.

Working principle of planetary gear transmission

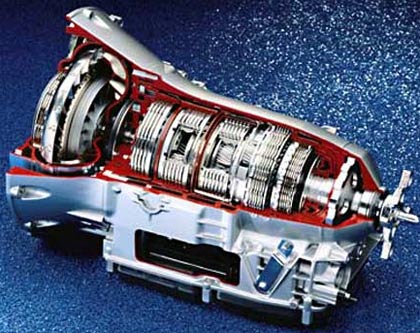

When you look inside an automatic gearbox, you see a separate set of parts in each reasonable space. Among those things, you see:

- A planetary gear transmission.

- A set of belt brakes is used to lock parts of the planetary gear transmission.

- A set of three wet working clutches in the oil is used to lock parts of the transmitter.

- A hydraulic system for controlling clutches and belt brakes

- A large gear pump for rotating transmission oil in the gearbox.

Most important in the system is the planetary gear transmission. The first is to make them have different matching ratios and then how they work. An automatic gearbox consists of basic planetary gear transmissions but is combined into one block in the gearbox.

Any basic planetary gear transmission has three main parts:

- Sun gear (S)

- Planetary gears and planetary gear rack (C)

- Outer ring (R)

Input

Output

Stand still

Formula calculator

Transmission ratio

A Sun ( S ) Planet Carrier ( C ) Ring ( R ) 1 + R / S 3.4: 1 B Planet Carrier ( C ) Ring ( R ) Sun ( S ) 1 / (1 + S / R) 0.71: 1 C Sun ( S ) Ring ( R ) Planet Carrier ( C ) -R / S -2.4: 1When locking two of the three components together will lock the whole structure into one block (the ratio of 1: 1). Note that the first ratio list above (A) is the number of transmissions reduced - the secondary axis speed (output) is less than the primary axis speed (input). Second (B) is the transmission number increasing - the secondary shaft speed is greater than the primary axis speed. Finally, the transmission number is reduced, but the direction of the primary axis is opposite to the secondary axis, ie the reverse number. You can check them according to the following simulation diagram:

A base gear transmission can perform different gear ratios without matching or disconnecting with any other gear. With two seamless base gear transmissions, we can get 4 speeds forward and one reverse speed. We will discuss the two basic gear transmissions that are attached later.

This automatic gearbox is also a planetary gear transmitter, called a double planetary transmission, the structure is like a single planetary gear set but the structure is two sets of planetary gears combined. It has an outer ring that is always attached to the secondary shaft of the gearbox, but it has two sun gears and two planetary gear sets.

Please see the following picture:

In the picture below: planetary gears placed on a rack. Take a closer look: the right planetary gear is lower than the left gear. The right gear does not match the outer ring, but it fits with the next planetary gear. Only the left planetary gears match the rim of the teeth.

Next you look inside the planetary gear rack. The shorter gears are fitted with smaller sun gears. Longer gears are fitted with larger solar gears while matching smaller planetary gears.

The simulation diagram below shows how clusters are assembled together in a gearbox:

No. 1

At number 1, the smaller sun gear is actively turning clockwise along with the torque converter's turbine. The price of planetary gear tends to rotate in the opposite direction but is retained by a one-way joint (only allowed to rotate clockwise) and the outer ring moves to the secondary axis. The sun gear has 30 teeth and the outer ring has 72 teeth, so the gear ratio is:

i = - R / S = - 72/30 = - 2.4 / 1

Because rotation is the opposite of the ratio 2.4: 1, it means that the direction of rotation of the secondary axis is opposite to the primary axis. But the dimension of the secondary axis is the same as the dimension of the primary axis. The first planetary gear set matches the second gear set, and the second planetary gear wheel rotates the rim of the tooth. This combination has reversed the movement. You can see that this will also make the solar gears larger than the rotator, but because the clutch is releasing, the larger solar gears spin smoothly in the opposite direction of the turbine (counterclockwise).

No. 2

This gearbox does really sophisticated things to get the right gear ratio for number 2. They act as two planetary gear sets that work together on a common planetary gear rack.

The first floor of planetary gear prices uses large sun gear to replace the tooth ring. So the first floor consists of solar gears (smaller sun gear), planetary gear rack and gear ring (large sun gear).

The primary axis is the small sun gear shaft, the ring gear (large sun gear) held tightly by a belt brake, the secondary shaft is the planetary gear rack. For this layer, with the sun gear as the primary axis, the planetary gear price is the secondary axis, the ring is fixed, we have the following formula:

1+ R / S = 1 + 36/30 = 2.2: 1

The planetary gear rack rotates 2.2 times when the small sun gear turns around. On the second floor, the price of planetary gears acts as the primary axis for the second planetary gear set, the larger sun gear (fixed hold) acts as the sun gear, and the ring gear plays game output, so the gear ratio is:

1 / (1 + S / R) = 1 / (1 + 36/72) = 0.67: 1

To get a total deceleration in the second number, multiply the transmission ratio of two floors together. 2.2 x 0.67 = 1.41. This seems unreasonable, but the reality is that.

Number 3

Most automatic transmissions have a ratio of 1: 1 in number 3. You remember that in the previous paragraph we knew the ratio of 1: 1 was due to the second key of any 3 parts of planetary gear. This is really easier and we only need to do one thing to lock the solar gears with the turbines.

If both solar gears rotate at the same speed, planetary gears will be locked because they can only turn in the opposite direction. This results in locking the gear ring with planetary gears and all turning on the same block to create a 1: 1 gear ratio.

Speed up

As mentioned above, the speed increase is the output speed greater than the input speed. Speeding is the opposite of the nature of the gearbox. In this transmission mode, the transmitter is set up with two planetary transmitters into a working transmitter. In acceleration mode the shaft is connected to the planetary gear rack via clutch. Small sun gears run freely on the shaft, larger sun gear with brake belt accelerates retention. They are not connected to turbines, but are directly connected to the torque converter shell. Look at our diagram again, this time the rack of gears will be the input, the sun gear is fixed and the ring is the output. We have the transmission ratio is:

i = 1 / (1 + S / R) = 1 / (1 + 36/72) = 0.67: 1

So the secondary axis rotates about one turn when the motor rotates two-thirds of the ring. If the engine speed is 2000 rpm, the output speed of the gearbox is 3000 rpm. This allows the car to run at a high speed with a low and medium speed engine.

Reverse number

The reverse gear is similar to the number 1, except that the replacement of the small solar gear rotates with the torque converter's turbine, with the larger sun gear driven by the turbine and the smaller sun gear turning freely in reverse. The price of planetary gear braked by the reverse belt keeps. According to the equation in the previous section we have:

i = - R / S = 72/36 = 2.0: 1

So the gear ratio of the reverse gear is slightly smaller than the gear ratio of 1.

Transmission ratios

This gearbox has 4 forward and 1 reverse gear. Look at the table below:

Number

Input

Output

Fixed part

Transmission ratio

1 Sun gear 30 teeth 72 tooth ring Planetary gear rack 2.4: 1 2 Sun gear 30 teeth Planetary gear price 36 tooth gear 2.2: 1 Planetary gear rack Ring gear 72 teeth Gear wheel 36 teeth 0.67: 1 Whole number 2 1.47: 1 3 30 and 36 tooth gear Teeth ring teeth 72 teeth 1.0: 1 Straight transmission Planetary gear rack Ring gear 72 teeth Gear tooth 30 teeth 0.67: 1 Back 30 tooth solar gear Ring tooth 72 tooth Planetary gear rack -2.0: 1After reading the above information, surely you will be surprised how different the inputs are disconnected and connected? This is done by a series of disc clutches and brake belts inside the gearbox. In the next section you will know how they work.

Clutch and brake strip

For automatic transmission, when tucked in axial acceleration mode (connected to the torque converter shell, and flywheel) is connected to the planetary gear rack via clutch. Small sun gears run smoothly on the shaft, larger sun gears with brake belts accelerate to retain. Nothing is connected to the turbine, only the primary axis in the torque converter box.

For the gearbox to speed up, many details need to be disconnected and connected by clutches and belts. Planetary gear rack connects to torque converter box thanks to clutch. Small sun gear leaves the turbines so they can spin freely. Large sun gear is retained by a brake belt so it cannot be turned. Each gear shaft causes such a range of problems by shutting off the clutch and belt brakes. Look at a belt brake in the gearbox.

In this gearbox there are two belts. Belt brakes in the gearbox are all made of steel and surround most of the planet's outer rim and hold them tightly with the gearbox cover. They work thanks to the hydraulic cylinders inside the gearbox.

In the picture above, you can see one of the brake pads inside the gearbox cover. When the gear is removed, the metal lever is connected to the piston that activates the belt brake.

See the picture above and you see two pistons that can drive the belts. Hydraulic pressure makes pistons push belts to lock gear sets with gearbox covers.

Clutch in the gearbox is a complex cluster. In this gearbox there are 4 disc friction clutches. Each disc friction clutch is driven by the inner piston clutch by hydraulic pressure. Springs help clutch plates separate when hydraulic pressure decreases. Looking at the picture below you will see the piston and drum of the clutch. Note the sealing ring with the rubber seal of the piston, which is one of the details to replace when repairing and repairing the gearbox.

The next figure shows how to arrange friction plates and steel plates in order. The friction plates located inside will be connected to one of the gears and the outer steel plates are locked to the gearbox's cover. The friction discs need to be replaced when repairing the gearbox.

The complexity of automatic transmission

The automatic transmission in your car needs to do a series of complicated tasks. We can hardly know how many different operations while it works. However, the main characteristics when it works will be described in the following example:

- If the vehicle is in acceleration mode (only with 4-speed gearbox), the gearbox will automatically select the gear alignment to the vehicle speed and accelerator position.

- If you increase the gas gently, the gearshift will happen more slowly than when you emphasize the accelerator pedal.

- If you lift your foot off the gas pedal, the gearbox will automatically switch to lower numbers.

- If you take the shift lever to a lower number, the gearbox will shift to a low number unless the vehicle is moving too fast with that number. If the speed is too fast, it will wait for the speed to slow down accordingly and then switch to the lower gear.

- If you need to select the number at 2, it will only decrease or increase the number to 2, even if the car stops, unless you move the shift lever.

Have you ever seen anything like this? It is really the brain of an automatic transmission, it operates all functions and more. Hydraulic oil grooves come in many different positions in the gearbox. Sinks in metal objects are the most efficient oil paths, without them, how many pipes can connect parts in automatic transmissions. Let's first talk about the key components of the hydraulic system, then we see how they work together.

Automatic transmission has a hydraulic pump, usually a gear pump. This pump is installed right on the gearbox cover. It draws oil from the container at the bottom of the gearbox and pushes oil into the hydraulic system. It also provides oil for the cooling system of the gearbox and the torque converter.

The inner gear of the pump connects with the torque converter's cover, so it rotates according to the speed of the motor. The outer gear is rotated in the inner gear by its teeth, the hydraulic oil from the container is sucked onto this side of the crescent-shaped space (pictured above) and pushed the oil to the other side onto the hydraulic system. .

Operating the oil system is an intelligent regulator that can tell the gearbox how fast or slow the vehicle is moving. It is connected to the output of the gearbox, so the faster the vehicle moves, the faster the tuner is rotated. Inside the regulator is a pressed spring valve that can be opened depending on the quick rotation of the regulator, the faster the regulator rotates, the larger the valve opens. The oil line from the pump to the regulator is passed through the secondary shaft of the gearbox.

The faster the car runs, the bigger the valve of the regulator and the greater the pressure of the hydraulic system .

For proper gear shifting, the automatic gearbox must know which load the engine is working at. There are two ways to identify this. Some cars have an engine throttle cable with throttle in the gearbox. The deeper you press the gas pedal, the greater the pressure exerted on the throttle valve. Other cars use vacuum valves to supply pressure to the throttle.

The position control valve needs to select the number that indicates where the number is located. Depending on which number is used, the valve will provide the appropriate oil line. For example, if the gear lever is at number 3, the valve will provide a cycle to prevent it from being pinned to another number.

The gear shift valve provides hydraulic pressure to the clutch and belt brakes to bundle into the gear. The hydraulic valve body of the gearbox contains several gear shift valves. The shift valve will decide when to move from one number to another. They are pumped to supply oil and push the oil flow to one of two loops to control the gear in the number to use.

The gear shift valve will stop shifting when the vehicle accelerates too fast. If the car accelerates smoothly, the gearshift will appear at a lower speed. See what happens when the car accelerates gently.

As the speed increases, the pressure from the regulator increases. This force forces the valve to switch the closed loop of the first number and opens the second digital loop.

When the throttle suddenly increases, the throttle valve provides greater pressure for the gear shift valve. This means that the pressure from the regulator needs to be higher (and the vehicle switches to a faster gear) so the gear shift valve moves to the second gear.

Each gear shift valve takes on a different pressure range, so when the vehicle moves faster, the 2-to-3 shift valve will continue to work, because the pressure from the regulator is high enough to activate the valve. this.

Electronic-controlled gearboxes appear in some new cars that still use hydraulic systems to control disc clutches and belt brakes. But each hydraulic loop is controlled by an electromagnetic coil. This makes the gearbox more flexible and allows for better system control coordination.

In this last paragraph, we study some more automatic control methods that this gearbox uses. Electronic control gearboxes also add more perfect control parts. In addition the control of the engine speed and throttle position is added, ie the gearbox controller also controls the engine speed, and monitors the ABS system if the brake pedal is pressed down. to ABS mode.

overview

Using the above knowledge and with advanced control system based on fuzzy logic - control method using artificial intelligence, electronic control systems can also do the following:

- Move down to low gear automatically when the vehicle downhill to control speed, take advantage of engine brakes and limit wear of brake pads.

- Increase the number of brakes and when slipping the wheels to reduce the braking torque thanks to the engine

- Preventing the increase in the number of vehicles running on roundabouts and buckling roads.

What to say about the following: limit the increase in the number when you are driving on a roundabout and curve ?. When you drive up a steep hill, there is a mountain. If you meet straight lines, you need to choose the number that is on the 2nd you need to increase how much. If you meet a turning point and a downhill, you lift your foot off the gas pedal and brake. Most gearboxes will increase to 3 or speed transmission when you lift your foot off the gas pedal. Then when you accelerate from the turning point, they reduce the number. But if you're driving a car with a conventional mechanical gearbox, you're sure to let the car run in a single number throughout the journey. Some automatic transmissions have advanced control systems that can recognize the fact that you are continually cornering, it will not perform continuous increase or decrease.

Quang Hung (translation)

- Things you don't know about AK-47 guns

- Steer-by-wire electronic steering system

- Principle of operation of air coolers

- Feast your eyes on the automatic fish fillet line with incredible precision

- Principle of operation of the clutch

- The principle of operation of the differential

- Operation principle of safety belt

- Graphics card and operating principles

- How does air conditioner work?

- Structure and principles of microwave operation

- Principle of operation and charging process of lithium ion batteries

- Not the pyramid, this is the most valuable work that the ancient Egyptians left for posterity

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light