The principle of operation of the differential

You already know how the engine works and you also learned the working principle of a gearbox. However, in order to bring the engine's power source down to the wheels it is necessary to go through a final system, which is the differential. Differential set is usually installed with the final transmission, also known as a bridge.

The differential on the car has three main tasks:

- Transfer the motor's torque to the wheels.

- Acting as the final deceleration mechanism before the torque travels to the wheels.

- Transfer torque to the wheel while allowing them to rotate at different speeds.

Through this article we will know why your car needs the differential and then let's study its working principle and learn about some of the current automotive differentials.

You should be aware that the wheels spin at different speeds, especially when spinning. Look at the simulation diagram below. Each wheel will travel different distances when the car is cornered, the inner wheels get shorter distances than the outside wheels. That means the inner wheels will spin at a lower speed than the outer wheels.

For passive wheels, such as the front wheels of the rear-wheel drive vehicle, nothing connects the movement between them and operates independently of each other. However, the rear wheels have a link to get the same power from a single engine and a single gearbox. Without the differential, the two rear wheels will be locked together, forced to rotate at the same speed. This will make it difficult to turn around. For the car to be cornered, make sure a wheel will spin. With the current technology of manufacturing tires and concrete roads, the impact force will make a wheel spin. This force will be transmitted from one side wheel to the other through the wheel shaft, increasing the torsion force acting on the wheel shaft.

What is the differential?

The differential is a device used to divide the motor's torque into two lines, allowing the two sides of the wheel to rotate at two different speeds. We can find the differential in all modern cars and trucks, and especially in fully autonomous four-wheel vehicles. Each active bridge of these vehicles needs a differential and naturally between the front and rear wheels is also needed because when the cornering, the distance that the front and rear wheels are also different.

For semi-active four-wheelers, there is no need for differential gear between front and rear wheels; instead, they are locked together to move at the same speed. This explains why these cars get stuck on the concrete road when the four-wheel-drive system is used.

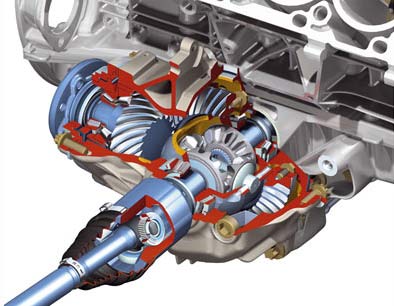

Will the wheels be turned at different speeds? We have just started with the simplest form of bridge differential, also called open differential. Here we will come up with some other terms. The image below will tell us some of the main components of an open differential.

When the car moves straight on the road, both wheels spin at the same speed. The gear at the input will make the gear ring and the differential shell rotate, there is no one gear of the rotary differential, the two edge gears are locked together and with the differential cover.

Notice that the input gear is much smaller than the ring gear, this is the last pair of deceleration gears of the car and their gear ratio is the gear ratio of the last transmission. When saying the final gear ratio is 4.10, it is 4.10 times more than the input gear.

When the car is cornered, the wheels will have to spin at different speeds. In the picture above, you can see that the gears on the differential shell will rotate as soon as the car starts to change direction, allowing the wheels to move at different speeds. The inner wheels rotate slower than the differential shell, while the outer wheels turn faster.

Open differential - when straight motion

Problems and troubles? Open differential sets always provide a fixed torque for each wheel. There are two determinants of the supply of torque to the wheels, the device and the traction. In dry road conditions, good grip force, the value of torque supplied to the wheels is limited by engines and gears; but in conditions of poor grip such as vehicles traveling on ice, the value of torque is limited by a point at which the wheels slip. So, even if the engine of the car is as strong as it is, the torque will not be transmitted to the ground because the wheels are spinning. At that time, if you deliberately acted harder, your wheels were spinning faster, but the car was still in place.

If you've ever driven on ice, you'll know the trick to make it easier to depart your car. You should not depart with number one, instead you should try to use the number two or even the number three. This will ensure that the car's gearbox provides low torque and so the car will probably "crawl away" without being "three minutes".

However, what happens when one side of the wheel has good grip and the other side is on the muddy? This is a problem that the open differential will have to work to solve.

Keep in mind that the open differential always provides the same torque for both wheels, and the maximum torque value will be limited where the wheels do not slip. It does not take much torque to make a wheel slip on the ice but the wheels with good traction only get the same torque value. Your car cannot get the optimal road grip.

More complicated is 'Off road'! In addition to the above disadvantages, open differentials can also cause you much more trouble when you drive on bad roads. If you have an active truck or a four-wheel utility vehicle, with an open differential for both front and rear wheels, you may be bogged down. Remember that we are working on open differentials that always provide the same torque for the wheels. If a front or rear wheel is not trapped, they will rotate freely.

The solution to this problem is the limited slip differential (LSD or positraction). This differential differential uses a variety of mechanisms to make the differential set active when cornering. When a wheel fails to rotate, they will shift the useful torque to the side of the wheel without slipping to effectively utilize the engine torque. Here we learn about the types of LSD, including clutch-type LSD, the viscous coupling, locking differential and Torsen differential.

Differential slip limit clutch type-clutch LSD

This is probably the most common type of limited slip differential. This type of differential has all the components of an open differential, but there is an additional spring box and a clutch. Some sets have a conical-like clutch synchronized in the mechanical gearbox.

The spring box pushes the side gears apart from the clutch plates being attached to the differential cover. All gears rotate with the casing when the two wheels rotate at the same speed, and there is no need for this clutch at the moment. But if something forced a wheel to spin faster than the other wheel, such as when cornering, for example, the clutch immediately started. It works against both wheels turning at the same speed. If a wheel wants to spin faster than the other wheel, it needs to make the clutch slip. The hardness of the spring and the friction force of the clutch will determine the torque value that will cause it to slip.

Going back to the above situation, if one wheel rolls on the tape and the other wheel has very good traction, with this limited slip differential, even the skid wheels cannot transfer torque to the ground. The cake on the other side will also transmit enough torque so that the vehicle moves away from the swamp. The torque supplied to the wheel that is not on the tape will balance the remaining torque value after making the clutch slip. As a result, you were able to move forward over the muddy.

Viscous Coupling (Viscous Coupling)

Adhesive joints are often seen on vehicles with fully active wheels. It is used to connect the rear wheels to the front wheels so that when a pair of wheels fails, the torque will be transferred to the other pair of wheels.

The adhesive joint has two sets of friction discs placed inside a closed space filled with liquid (usually special hydraulic oil) with high viscosity. Each set of friction discs is connected to one end of the shaft. Under normal conditions, both sets of friction discs and hydraulic oil in the coupling rotate at a certain speed. When a pair of wheels tries to spin faster, which may be slipping, for example, the friction discs corresponding to the faster spinning wheels are also spinning faster. At this point, the hydraulic oil in the space between the two sets of friction discs will work the same set of friction discs quickly to follow. This will cause the torque to be transferred from the faster rotating wheels to the slower rotating wheel, making the wheel more slippery.

When the car is cornered, the speed difference between the wheels is not as big as when one of them slips. One of the two sets of friction discs rotates faster than the other (corresponding to the more sliding wheels), the greater the amount of torque that is used by the adhesive coupling kit. So the effect of this type of coupling when the car is cornered is not available, so the biggest drawback is, obviously: there is not a bit of torque to be converted before the sliding phenomenon begins.

To make it easier to understand, we will learn a simple illustration: You put a glass plate, deep, small, can hold a duck egg on a rotating base placed on the table. Dexterously beat the egg into the dish that the yolk does not break. At this time, the egg yolk is located in the middle of the plate and the surrounding white. Turn the disk abruptly. Notice that you will see, at the beginning, the egg yolk does not rotate with the plate, but only after a while it turns with the plate. This can be explained by the viscous friction of the egg white which makes the yolk turn along with the plate. If when the disk and the yolk are spinning together, suddenly you hold the disc, then the yolk immediately turns slowly and then stops following the disc. Contact with the above joint, we can see that the plate and the yolk are two sets of friction plates and chicken egg whites have the same effect as hydraulic oil, and their working principle is as shown in the above example.

Differential locking locking and differential torque sensor Torsen

The differential lock is very useful in case your car runs on a very bad road. Its structure is similar to the open differential but is combined with hydraulic, pneumatic or electric structure to lock the output gears together. This differential mechanism is controlled to open and close mainly by a switch and when it operates the wheels rotate at the same speed.

The Torsen differential is a complete mechanical device, it is not electronically controlled, has no clutch and does not have any hydraulic power.

Torsen differentials (combining 'torque' and 'sensing', meaning the torque sensor) work as an open differential when the torque value of each wheel is balanced. But as soon as a certain wheel loses its grip, the difference in torque leads to Torsen differential gears in contact. The design of gears in the differential will determine the torque difference ratio. For example, if a special Torsen differential is designed with a 5: 1 difference ratio, it will be able to provide torque to the wheel with a good grip force 5 times greater than the skid wheel.

These devices are often used in cars with fully active wheels with high efficiency. Like sticky joints, they are often used to convert the power between the front and rear wheels. In these two categories, the Torsen differential is better than the adhesive coupling differential because they transmit torque as soon as the slip phenomenon can occur. However, if a pair of wheels lose their grip completely, the Torsen differential will not be able to provide any torque to the other pair of wheels, because the difference will determine how much torque is transferred. change, and of course 5 times 0 will have to be 0.

Ngoc Hai (Translating)

- Operation principle of automatic transmission

- Principle of operation of air coolers

- Operation principle of safety belt

- Graphics card and operating principles

- Steer-by-wire electronic steering system

- Structure and principles of microwave operation

- Principle of operation and charging process of lithium ion batteries

- Straight line is not the fastest way?

- Not the pyramid, this is the most valuable work that the ancient Egyptians left for posterity

- Principle of operation of wind turbines

- Electric shoes

- How does the double-sided mirror in the interrogation rooms work?

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light