Smart pump helps to deliver medicine

An advanced micro-pump helps to transfer a very small amount of solution - like medicine - a precise and flexible. Flexible compounds and electrical control mechanisms ensure that the wire tube will operate correctly - both inlet and suction.

Medicines sometimes have to be dispersed into very small amounts. Just a few tenths of a milliliter is ideal for treating patients. Micro pumps are mostly supportive of this small dose of medicine. The same pumps have been manufactured and have been optimized for over 25 years. They are applied in many areas - from medical technology to small manufacturing technology - to any small volume that needs to be dosed with extremely precise levels.

However, the aforementioned micro-pump systems are often not as flexible as they are expected: They usually only operate in one direction, bubbling in the damaged solution during operation, they cannot withstand the particles that interfere , they have a fixed pumping path and they contain consumable parts such as valves or gears. Together with partners in research institutes and industries, researchers from Fraunhofer Research Institute of Materials IWM in Freiburg have invented an innovative pump system to solve these shortcomings: that is Ultra-small peristaltic pump can be controlled.

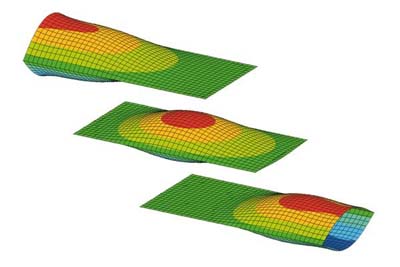

The new micro pump works just like a human esophagus: the solution is inserted from the left (top), then pushed by the contraction of the pump (middle) and exits to the right. (picture below).(Photo: Fraunhofer IWM)

IWM's project manager explained, 'Peristaltic pumps are an extremely complex system. It shrinks into ripples like human esophagus, and thus pushes the solution forward - it changes its own shape accordingly. To achieve this, we must use the entire range of different special materials and compounds'.

The researchers used PZT (lead-zirconate-titanate) thin films assembled by a method suitable for bend elements made of carbon fiber reinforced plastic (carbon-fiber-reinforced plastic - CFRP) and a flexible tubular shape.

Thielicke said 'The PZT material changes its shape as soon as you put it in the magnetic field. This helps us to control the pump system according to the electric field method. In addition, special adhesives collect different components of the pump system together. Thanks to the special electronic control, small amounts of solution can be pumped correctly through the system.

Peristaltic pump system has undergone the first functional tests. Currently researchers are conducting micro-peristaltic pump applications into different applications. Thielicke said 'We will work with simulation models to do this. We will calculate in advance how the structure of the pump is modified to disperse other dosages or other types of solutions. This will help us save time and money in manufacturing. "

- Smart medicine vial

- Foot pump

- Non-fuel water pump 'made in' Vietnam

- Ground-based scientist and unique water pumping system

- Brother: The boy has a battery-powered heart

- Video: Smart bed helps prevent snoring

- Preserving agricultural products by 'hybridization' of drying technology

- Water pump by ... motorcycle engine

- Convenient deep pump in all terrain

- Water pump does not need fuel

- New generation heart pump

- The first smart shirt on the market

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water