Successfully developing metamorphic metal, the future of creating T-1000 like in 'Terminator' will not be far away

Rapidly changing the shape of alloys in a reversible way: Chemists have taken a new step on the road to developing reconfigurable technology.

When seeing the words "liquid metal", sci-fi fans will associate the nearly indestructible T-1000 robot in the legendary blockbuster "Terminator" - made from "metal". liquid", can change the shape at will.

Liquid Metal is 1.5 times stronger than steel and lighter in weight.

Liquid Metal is a durable compound that is 2.5 times stronger than Titanium alloy while being lighter in weight. 1.5 times stronger than steel and lighter in weight. Hard to be permanently deformed 2-3 times compared to traditional metal. Completely non-corrosive. Allows for thinner but stronger shells.

A research team at North Carolina State University has taken an important first step on the road to making such alloys.

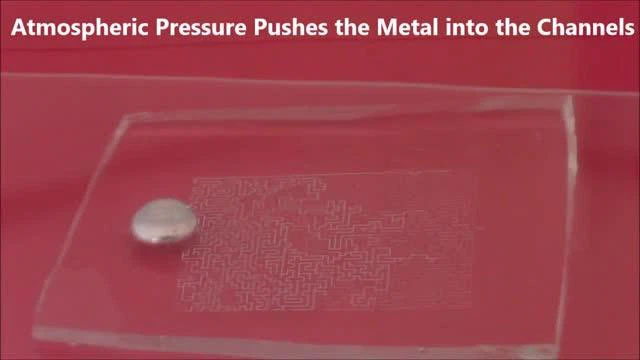

By applying a low voltage to a conductive liquid (in this case, an aqueous solution) and tweaking its strength, the researchers changed the shape of gallium-indium alloy droplets in near water. like an instant, causing them to either spread out into long bands or contract into spheres.

"By making the metal flow, change shape, we can create modified structures," explains lead researcher Michael Dickey.

The main application chemists have in mind is creating small, tunable metal antennas: the same material can be distorted to send and receive signals.

Likewise, the material can be used to create electrical circuits that can spontaneously change the layout of electrical wiring, much like a nervous system can make or remove most connections. to maintain the optimal state.

This material can be used to create electrical circuits that can change the wiring layout.

Benoit Grosdidier, a specialist in liquid metals at the University of Lorraine in France, believes that the solder currently used in microelectronics will be replaced by such alloys.

"The key to the welding process is the spread of the weld metal and similar 'substrate wetting', so that liquid metal can replace the toxic metals being used," explains Benoit Grodidier. present (such as lead) or other metals are in short supply".

For example, tin, often used for soldering because of its excellent ductility, however we are facing the depletion of our tin reserves; The formula changes ductility by applying a voltage that promises to replace it with other, more abundant metals.

Michael Dickey admits: "We are still in the early stages of research. However, he emphasizes the huge advantage of liquid alloys: these alloys are not like mercury, they are non-toxic and subject to change. desired shape".

Everything happens on the microscopic level, stemming from the forces that ensure the liquid metal droplet stays cohesive when it comes into contact with air or liquid - it determines the final shape of the liquid metal. This force is the surface tension, on the surface of the pond can be observed a swarm (often called a water spider) walking on the surface of the water without the liquid surface flowing. It is the surface tension of water that can bear the weight of its stride.

The surface tension of gallium-indium alloys is seven times higher than that of water. In contrast to water, which disperses and flows on some surfaces, gallium-indium alloy droplets are spherical on most surfaces to minimize the surface area's exposure to the outside world.

But when these droplets are in a conductive solution connected to a power source, the metal atoms on their surface react with the charge in the solution to form an oxide layer. This oxide layer can reduce the surface tension of the gallium-indium alloy droplet and affect the shape of the droplet, so that the alloy's shape can be changed by varying the voltage applied to the conductive solution. .

The oxide acts as an intermediary between the metal and the water in the conductive solution.

The researchers found that the oxide acts as an intermediary between the metal and the water in the conductive solution. Michael Dickey explains: "The oxides have gallium atoms, which on the one hand have an affinity for the liquid metal; on the other hand, they have molecules similar to that of water (the hydroxyl group), so they are also hydrophilic. country". A potential difference of less than 1 volt can be enough to create an oxide layer on the surface of the liquid metal that reduces the surface tension to almost zero, so that the metal droplets no longer retain their spherical shape. them and become "a puddle of water". In addition, the researchers were also able to push the liquid alloy to flow in a specific direction, and the change is completely reversible: as soon as the power is cut off, the oxide layer disappears, and the alloy returns to its shape. original form,back into dense spherical droplets within a second.

The liquid alloy can flow along the path established by the researchers, and then spread out instantaneously to take on different shapes as if it were life-like, like a T-1000 collecting robot. small to a more "alum" level.

- The first liquid metal network was successfully built, the future of 'Terminator' T-1000 is not far away?

- Decoding the metal magic 'transformation' is very popular with science

- Solve the most spooky metal series in the world

- Super-hard metal helps build futuristic spacecraft

- Scientists successfully developed transfigured liquid metal

- Detecting new transformation metal

- Find a way to kill cancer cells in liquid metal

- Catch the metamorphic octopus in the Gulf of Thailand

- Applications of Silver metal from the past to the present

- Found creatures in the deepest area of the Pacific

- NASA plans to conquer metal planet in the near future

- Attach metal to glass

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste