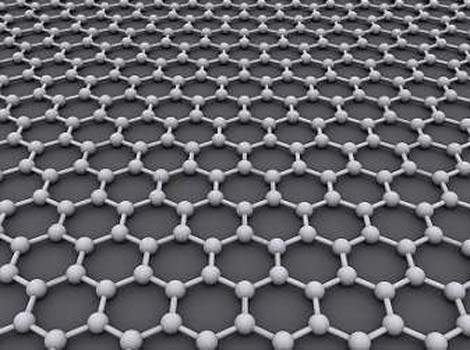

Two Russian-based physicists who won the Nobel prize this year have announced the invention of a new substance, fluorographen, that can replace silicon in electronics and other applications.

Based on graphene - the marvelous material that brought Andrei Geim and Konstantin Novoselov the Nobel Prize for Physics in 2010, was awarded December 10, scientists synthesized many other new materials.

Izvestia newspaper reported that recently, Geim and Novoselov have cooperated with other British, Chinese, Dutch, Polish and Russian researchers to synthesize a new compound from graphene, fluorographen . This is a very durable and semiconductor compound, but it is resistant to high temperatures and chemical resistance. Regarding mechanical strength, it only lost to graphene.

Inheriting the durability of graphene, fluorographen has many advantages over other substances. It is very convenient to make semiconductor components, which have fast transmission and extremely small size, used in microelectronic products.

In order to switch from silicon to graphene, it is necessary to find graphene derivatives with electronic transmission properties with minimum energy. So far, only two substances have been found: graphene oxide and hydride. These two substances have drawbacks because their inclusion in microelectronic devices is too complicated: they are unstable and have a heterogeneous structure. Scientists are trying to find graphene-based substances without these two serious drawbacks. And it seems that the compound was found: fluorographen .

It has long been known that carbon compounds with fluoride, such as politetrafluoetilen (commonly known as Teflon ), are widely used in the food industry and in living equipment. This time, scientists have created a new technology to combine graphene with fluoride and obtain a heat-resistant and chemically stable material and excellent semiconductor properties and high mechanical strength. up to 1.5 times.

In the authors' opinion, fluorographen was created, which is a substance that opens up potential applications not only in the microelectronics industry, but also can replace Teflon to make protective coatings with more properties. superiority.

Daily use inventions come from universities

Daily use inventions come from universities Special weight loss device helps prevent appetite

Special weight loss device helps prevent appetite 8 inventors were killed by their own inventions

8 inventors were killed by their own inventions Iran invented a motor car powered by water

Iran invented a motor car powered by water