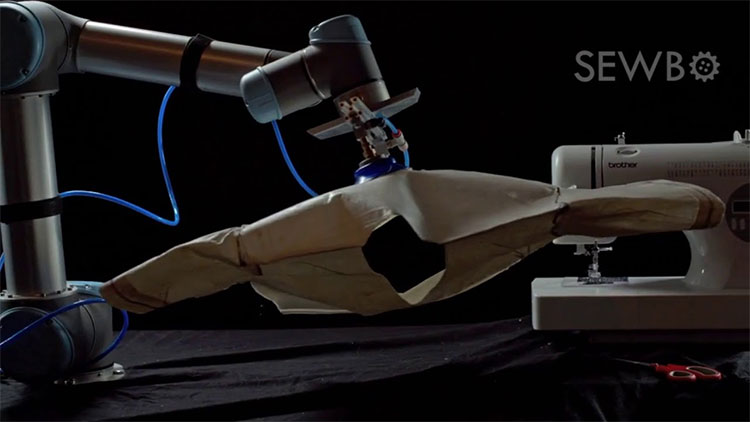

Sewbo - Tailor Robot promises to help automate the entire process of making clothes

Sewbo is the first robot in the world to be able to use a sewing machine to create a complete T-shirt, by stitching together 'frozen' fabrics with chemicals.

On the positive side, the machine could end the exploitation of labor in the production of cheap garments, but if viewed in a negative way, Sewbo will threaten the jobs of workers. sewing all over the world. It is known that this is the product of a website programmer named Jonathan Zornow, currently living and working in Seattle (USA).

In the process of making clothes , each machine will take on different roles such as weaving, stitching, cutting, etc. However, until now, no one machine can complete a shirt otherwise there is support for human participation. Designed to "create high-quality clothes at low cost , " Sewbo overcomes the difficulties traditional robots face when performing manipulations of soft fabrics, by hardening them temporarily. thanks to a chemical commonly used in 3D printing technology.

Sewbo production line if established promises to reduce social and environmental costs.

The entire Sewbo system is made up of an arm manufactured by Universal Robot for about $ 35,000, a traditional sewing machine, and a reusable thermoplastic container. Two pieces of hard material will be stitched together thanks to an industrial sewing machine, with the help of robotic arms. Temporary hardening chemicals of fabric pieces can be dissolved in water, so after finishing sewing into a shirt, the robot will immerse it in some hot water and the shirt will return to its state. common sense.

"It will shorten the supply chain and reduce time (for stages), factors that prevent the fashion and apparel industry, help reduce the complexity of today's global supply network." Zornow said, because the robot arm can be programmed to perform repeated actions, Zornow hopes future clothing manufacturers will use an assembly line with the participation of Sewbo, and each robot will complete a small task before moving it to the next robot Sewbo production line if established promises to reduce social and environmental costs.

Zornow is hoping to be able to work with names in the fashion industry who are really interested in automating clothing production.

- Too lazy to wear clothes? Don't worry, there are robots doing it for you

- Robot reporters in the future?

- Laundry tips and quick drying clothes when it rains wet

- Underwear company revealed about astronaut's attire

- Robot assisting

- Video: The process of creating a tie by hand

- Robot replaces the legs

- If you know how to fold this, you can bring a traveling wardrobe

- Continuously dig graves, wear new clothes and process dead people around the village

- The HOSPI-R robot helps nurses distribute drugs

- Germany developed the most advanced robot in the world

- Great packing technique without wrinkling clothes

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot Finland installs the world's first sand cell system

Finland installs the world's first sand cell system