3D printed organs bring hope of cheap transplants

Researchers have successfully developed a method of 3D printing of various body structures such as heart, arteries, brain and bone, providing opportunities for cheap organ transplants for patients in the future.

In the near future, there will be cheap 3D printed organs

According to Live Science, in the future, this technology will help create soft 3D implants, providing the opportunity to replace organs for patients. The living tissue will grow here to form different internal organs.

3D printers are being used to create a variety of products, ranging from materials such as ceramics, plastics, glass, metal, even living cells. It works by overlapping 2D printing layers on each other to form 3D objects.

However, current 3D printers only print solid objects. In the medical field, solid devices support patients such as hearing aids, dental implants, and prosthetic hands all use 3D printing technology.

"Metal, ceramics and hard polymers have been 3D printed for a long time. Soft materials need special support during printing, because objects can collapse under its own weight ," Adam said. Feinberg, Carnegie Mellon University biomedical engineer, lead author of the study shared.

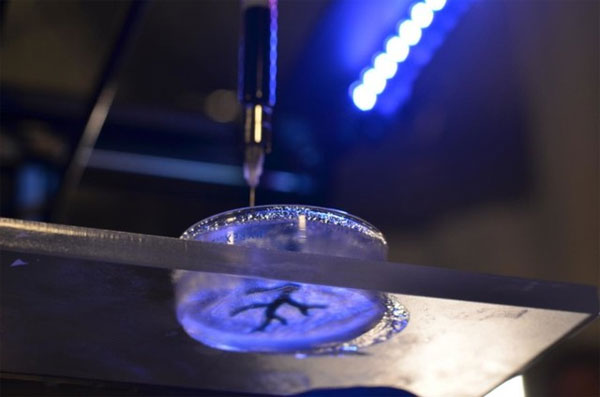

3D printing frame of coronary artery structure.(Photo: Carnegie Mellon University College of Engineering).

To solve this problem, the process of producing soft implants requires a process called "biological printing". Soft materials will be printed in a support liquid tank containing gelatin powder.

"This process will help us accurately locate soft layers of materials when printing , " Feinberg said. "Basically, 3D printers will create a framework for tissue and organ development."

In this way, the team printed tests of prototype frame structures such as the femur, coronary artery, 5-day-old chicken heart embryos, folds outside the brain. Printing materials are biological materials such as collagen (collagen) on tendons and ligaments. The resolution of these prototypes is 200 microns, twice the width of a human hair (100 microns).

"We use materials such as glue, blood (to create blood clots), alginate (which is abundant in marine algae), materials that the human body itself uses, to as a printing material , " Feinberg said.

"We can build technical frameworks that use these materials in complex structures that fit the body's tissues and organs."

The liquid that supports the sticky printing process on the product can be easily removed by heating to human body temperature. This temperature does not damage biological molecules or product cells, according to the research team. While the printing process of an organ organ is a time-consuming process, believe scientists have planned to integrate heart cells into the structural framework, so that they can develop into heart muscle.

This new method can help the cost of biological 3D printing from $ 100,000 to $ 1,000. It also uses an open source software for interested people to access and improve.

The study was published in detail in Science Advances magazine on October 23.

- Not only for meat, pigs have a much higher purpose

- A new step in creating alternative organs for humans

- Catching eyes when watching human cells are 3D printed with unprecedented technology

- New hope for people who need transplants: Successfully cultivate new lungs

- Taking organs of pigs to transplant for future people

- What kind of organs should be eaten

- 'Cultivation of human organs in pigs' bodies

- Organ transplantation ... 3D printing

- Unbelievable applications of 3D printing technology

- 3D blood vessels

- Artificial iris reacts to light like a human eye

- Eating organs easily accumulates toxins but following these 3 ways will not be toxic

Green tea cleans teeth better than mouthwash?

Green tea cleans teeth better than mouthwash? Death kiss: This is why you should not let anyone kiss your baby's lips

Death kiss: This is why you should not let anyone kiss your baby's lips What is salmonellosis?

What is salmonellosis? Caution should be exercised when using aloe vera through eating and drinking

Caution should be exercised when using aloe vera through eating and drinking