How is the 'super durable' sapphire screen made?

Perhaps many people already know of sapphire screens, the ultra-durable screens rumored to be used in the upcoming Phone 6. Many outstanding advantages of this type of screen have been raised, but there will be many people asking the question: Why is it possible to create a smartphone screen from this expensive gem?

We must be no stranger to sapphire gemstones sold in jewelry stores. But to make a screen for millions of millions of devices moving from that kind of gem, it seems too . expensive. In fact, the sapphire crystal used to produce smartphone screens is not a gem that is exploited in nature, but created in the laboratory. And instead of having a variety of colors, this sapphire is transparent because it does not contain colored impurities for natural sapphire.

So how exactly is this "miraculous" material made?

Step 1: Production of sapphire crystal

The process of producing sapphire crystals begins with the kilns as shown in the picture, where extremely high temperatures and pressures will turn aluminum oxide into sapphire crystal.

According to the Pocketnow video (posted at the end of the article), "sapphire beads" the size of a shoe polish box will be placed at the bottom of the metal container (called a cooking pot).

"Sapphire seeds" will be mixed with a form of aluminum oxide and un-crystallized sapphire material called "crackle" as shown below.

Next, the cooking pot will be placed in the oven. The furnace temperature will be increased to 2200 o C, hot enough to melt the mixture. The molten material will then be put through a series of cooling cycles for a period of nearly two weeks. This is when sapphire is crystallized. The product is a cylindrical sapphire block, named "sapphire boule".

The boule sapphire block will be cut and cut for various purposes, including the production of LED screens and aircraft windows.

However, to create sapphire displays for smartphones, the cylinder will be cut into smaller blocks. These blocks are called "sapphire wafer" , from which thin sheets of paper-like sapphire sheets will be cut into screens for smartphones.

Step two: Production of sapphire screens

GT Advanced has also introduced their own video on how to create "ultra-thin" sapphire plates with their technology.

First, the sapphire wafer block will be bombarded by high-energy protons (H + ions).

To carry out this process, the company GT Advanced used their ion-producing machine, named Hyperion 4 . Proton beams will bombard extremely high-speed wafer sapphire blocks so they can penetrate the surface of the block.

H + ions (protons) will form micro hydrogen gas bubbles below the wafer sapphire surface. Next, the wafer will be "cooked".

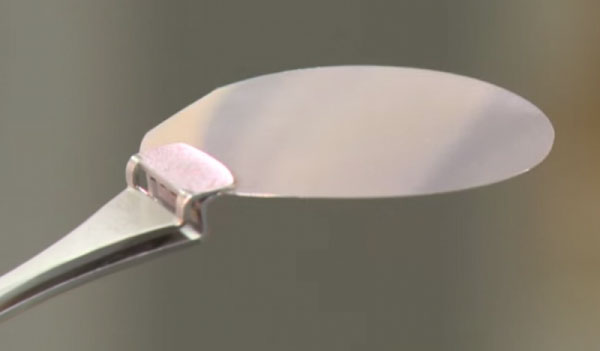

High temperatures will separate ultra-thin sapphire plates from the wafer. The process continues to repeat itself until the wafer is used up and we obtain a series of ultra-thin sapphire plates.

The final product is obtained here:

You can view the full video of Pocketnow page below to get a more comprehensive view of the production process.

- Smartphone screen sapphire will launch this year

- Glass smashed without breaking

- Discover China's super-durable sticky rice mortar

- Scientists create new materials that are as durable as diamond

- The world's largest blue star sapphire is priced at $ 100 million

- At the end of 2017, there will be smartphones using diamond screens

- Successfully made durable glass material, but made from wood

- Unveil the ultra-durable memory chip technology

- Super Screen Protector Sticker

- Super durable ball does not collapse despite being rolled by a truck

- Detection of super-durable materials from fire ants

- Super durable fabric

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?