How to quickly determine the shelf life (Shelf Life) of the product

Today, when customers choose to use a product, the first thing they care about is Shelf Life. So, what is the expiry date? How to determine how?

The expiry date is the commitment of the manufacturer to the customer, which is the timeline for which the goods are not allowed to circulate. In addition, when launching products to the market, some products are required to specify the expiry date such as food, food, food additives, cosmetics, pharmaceutical materials, animal feed, plant varieties, fertilizer.

However, how long is the expiry date reasonable? If the term is too short, if you can not do anything, you will see the distributor deliver the goods. But the goods are very good, still very good. If the term is too long, there will be plenty of time to distribute the goods to places. But when the customer bought it, oh well, the product was damaged. At that time, the light is reflected, heavy, the customer will gradually lose. That, no business wants it.

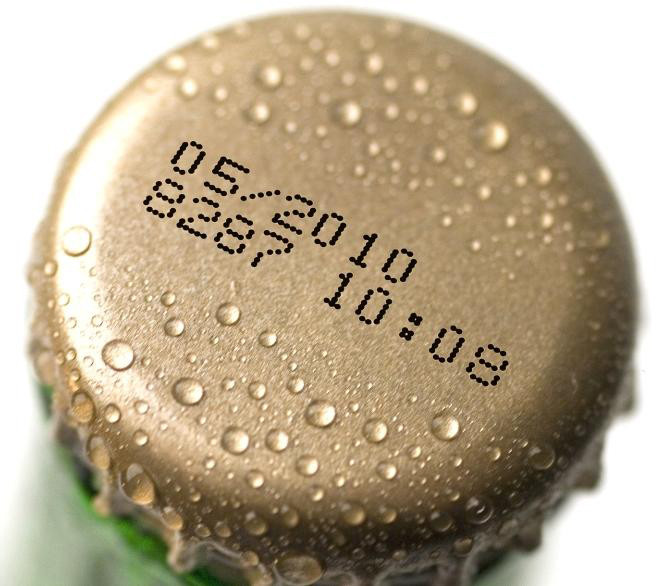

Shelf life of products usually printed on the packaging.

How to determine shelf?

A product has many criteria for determining quality such as microbiology, sensory, physical chemistry . Normally, the standards of products in Vietnam will be determined according to TCVN and some other international standards. like Codex. It is the manufacturer's responsibility to ensure the quality of the product is still in its expiry date. However, determining the optimal shelf life is always a problem for manufacturers.

In order to accurately determine the expiry date, it is necessary to periodically monitor the product from the beginning of production until one of the required standards of the product no longer meets the standard with the same storage conditions. on the market.

With a short-life product such as fresh cakes, fruits ., it's easy to track and determine shelf life. However, how can a shelf life of a long-life product such as milk powder, frozen meat, soft drinks be determined . when it is necessary to launch the product as soon as possible?

We cannot wait for months or even years to track and produce products. Therefore, there needs to be a faster way of determining. The following are some common methods for quick calculation of shelf life of products with an expiration reason due to degeneration over time. However, it is worth mentioning that despite the convenient and economical methods of quick-use calculation, it is necessary to monitor more products in normal storage conditions.

Method 1: Based on the shelf life of similar products

If the product under study A is very similar to the product B already on the market, we can estimate their shelf life will be similar. However, there are some notes when using this method as follows:

- Be sure about the similarity of the two products. Just a small difference in the production process or material can lead to a difference in shelf life. Therefore, this method should be used by industry experts with a lot of knowledge and experience.

- Need to check the control. Products are expected to have similar transformations in the same environment when they are together and have the same recession mechanism. Store these two products in parallel, check the control at different temperatures. If degradation of test sample A and reference sample B are the same at temperature areas, these two products can be assumed to have a similar shelf life at storage temperature.

We can use the same product to compare shelf life.

Method 2: Thermal acceleration

One of the ways to quickly determine shelf life is to accelerate the rate of product degradation . There are many ways to accelerate the rate of product dehydration, the most common being the thermal acceleration method (or the Q method) . Method Q assumes that product quality degrades in a constant Qn when the temperature changes a certain number. With a temperature change step usually 10 ° C, Qn is sometimes called Q10. With a known value of Q10, the expiry date can be calculated using the formula:

ts = t 0 .Q10.n

Inside:

- ts: shelf life under normal storage conditions.

- t0: expiry date at thermal acceleration conditions.

- n: thermal acceleration temperature (° C) minus normal storage temperature (° C) divided by 10 ° C.

For example, the shelf life of a product at 50 ° C is 32 days. Normal storage temperature is 25 ° C.

Then: n = (50-25) / 10 = 2.5.

Suppose Q10 = 3.

At that time, Q10.n = (3) 2.5 = 15.6.

Expected shelf life is usually: 32 days x 15.6 = 500 days.

The higher the Q10, the longer the expiry date. Therefore, accurately determining the price of Q10 is very important . As the example above, if Q10 = 2, the normal shelf life at 25 ° C will be 181 days, 2.7 times less than in case Q10 = 3.

However, it is not easy to determine the value of Q10 . The product may have many Q10 values due to many different degenerate types. The relative value of Q10 can be determined by storing the product at 10 ° C intervals, then determining the shelf life of the product at those temperatures. Each time the temperature is increased by 10 ° C, the product will reduce the corresponding shelf life to Q10 times. For example, a product has a shelf life based on color properties. Normal storage temperature is 30 ° C. If the product is stored at a temperature of 40 ° C (10 ° C higher than normal), the color fades twice. That is, the shelf life is reduced by 2 times. At that time Q10 = 2.

However, it is necessary to examine the shelf life of the product many times at different temperature zones to determine the relative value of Q10. In addition, not all products can identify Q10 in this way, especially food products.

The products are usually stored at both the accelerating temperature and the normal storage temperature. The results obtained at thermal acceleration will be used to calculate shelf life at room temperature. Storage results at room temperature will often be used to check the accuracy of the thermal acceleration method.

Method 3: Use mathematical models

The use of mathematical models for fast, economical results is not new in determining the shelf life of a product. However, for each different specific product there will be a different model. Therefore, it is very convenient but this method is not popular by thermal acceleration method. Following, please introduce a very popular mathematical model used in the UK on industrial cake products with mold-free shelf-life type. A recent report shows that 80% of bran produced in the UK is currently estimated to be used by this model.

Based on a large number of experiments conducted at the Flour and Baking Research Association (FMBRA) in the UK, the following formula has been developed to calculate the shelf life of stored industrial sponge cake at 27 ° C and 21 ° C, have ERH in the range of 74-90%.

At 27 ° C: Log10 A = 6.42 - (0.065 * ERH%)

At 21 ° C: Log10 A = 7.91 - (0.081 * ERH%)

A: number of days in the expiry date.

ERH: equilibrium moisture content of the cake (Moisture moves from the cake to the atmosphere, and vice versa until equilibrium is reached).

According to the above formula, the cake with a balanced moisture content of 88% will have an estimated shelf life of 21 ° C for 7 days, at 27 ° C for 5 days.

- Shelf life of new style

- Household items with limited shelf life

- Shelf life of sunscreen

- New method of fishery safety testing

- Marvel at the space below the Antarctic ice shelf at a depth of 300 meters

- Smart labels can change the color according to shelf life

- Why do canned foods have a shelf life of several years?

- Two ice cracks threaten the Antarctic research station

- Japanese glass inventors determine the level of fatigue and sleepiness

- Instructions for viewing the shelf life of cosmetics

- After many years, astronauts are about to eat noodles

- Students invent a small shelf, earning $ 2 million a year

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?