On November 4, 1862, the '6-barreled' Gatling machine gun was officially born

When people find new design principles that are more suitable for automatic guns, the Gatling gun gradually goes into oblivion though its later generations have really made a certain impression.

November 4 - Gatling 6-barrel machine gun was born

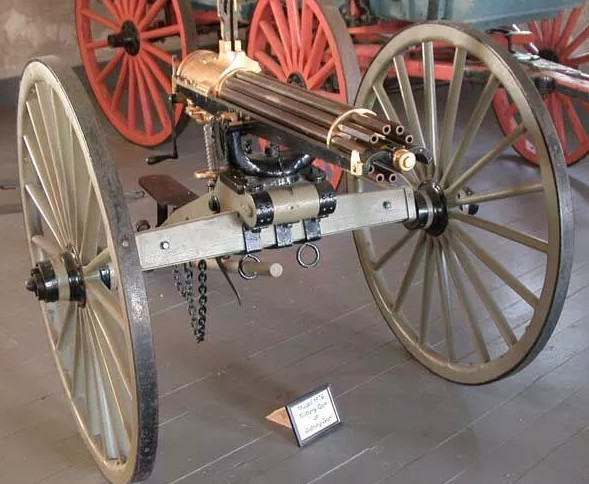

The predecessor of today's famous M134 Minigun is the Gatling "6-barrel" machine gun invented by Dr. Richard Jordan Gatling in 1861 and officially registered for patent on November 4, 1862. . Immediately after being certified, Gatling machine guns were immediately used in the US Civil War, when it was only hand operated instead of using a motor like today.

Picture of Gatling machine gun at a museum.

During its more than 45 years of operation, the Gatling machine gun moved from the position of the guide and the monopoly before being removed from the list of real combat weapons in 1911 by the US military. Basically, Gatling machine guns have met the needs of the military at the time, increasing the rate of fire by increasing the number of guns. Although it has been upgraded bit by bit through versions like M1881, M1893, M1895, M1900 and M1903, Gatling machine guns are becoming increasingly weak against juniors who follow the speed of shooting with only 1 The only barrel like the Maxim machine gun.

Of course, the Gatling gun is quite popular, but it quickly reveals its disadvantages: bulky, heavy, poor shooting accuracy, trouble-free operation and especially low firing rate due to dependence. on the gunner's spin, usually only about 200-300 shots / minute. Gatling also sought to attach the electric motor to the gun instead of human power, but the technical conditions did not find a solution to synchronize the rotating speed of the gun barrel with the lock barrel loaded so it did not completely overcome the disadvantages. of the gun. When people find new design principles that are more suitable for automatic guns, the Gatling gun gradually goes into oblivion though its later generations have really made a certain impression.

At the end of World War II, with the development of jet engines, experimental jets had achieved unprecedented high speeds, hitting flying targets became very difficult. At this time, the US military wanted a weapon with high firing frequency but it had to be reliable. In response to this problem, US General Electric (GE) restored Richard Jordan Gatling's idea of a multi-barreled gun. The Gatling revolver requires an external force to spin the barrel continuously. The new generation of jet aircraft promises to provide enough power to operate guns and ensure reliability over automatic weapons and fire points by gas extraction principle. Although the firing rate of each barrel is lower than a single gun, the total firing frequency of the six guns combined will result in a higher actual firing frequency.

In 1946, the US military made a contract with GE for the Vulcan project to test 6-barrel guns that could fire 6000 20mm bullets in a minute. The prototype T-171 was piloted in 1949 but not yet complete. The M61 Vulcan (M134's second precursor) had problems with the bullet belt, which was often tilted and slammed when shot, the reload system with no connecting belt was developed. Despite being reliable and having a "terrible" firing rate, the criticisms of M61 have been increasing in recent years due to its limited performance. Ballistic characteristics of 20mm ammunition are fast energy loss, destructive power and accuracy lost to Europe and Russia 25-30mm bullets.

Efforts to develop larger US Air Force bullets to replace M61 still yield very limited results. Another complaint point of Gatling machine guns is that they take 0.5 seconds to boot to the maximum rotation speed. In the first 1 second, the cannon fired only 70-75 shots and experts said that had lost the advantage of this gun to the revolver types, while the Gatling machine gun was more heavy and complicated.

M61 Vulcan.

In 1956, to develop a reliable, high-speed and effective weapon, General Electric re-engineered the 20mm M61 Vulcan machine gun into a new gun using NATO's 7.62x51mm bullet. The project achieved results and the guns were mass-produced when the gun's firing rate could reach 4,000 rounds / minute without the gun barrel being hot, ensuring continuous operation until the ammunition ran out. During the tests, the gun achieved a firing rate of 6000 rounds / minute, but was later lowered to 4,000 shots / minute due to the lack of a solution to cool the barrel. Then, thanks to the application of the technology of rapid heat-alloy technology, at the same time developing the cooling system for guns, so the M134 achieved a speed of 6000 transmitter / minute.

M134 Minigun has a complex structure, with an electric motor on the inside, which rotates the barrel while pushing the bullets on the barrel, knocking the detonator. The gun structure consists of multi-barreled bore assemblies paired together like a bundle of chopsticks, in the middle of a rotating shaft, behind the barrel assembly is a barrel lock with a lock number corresponding to the barrel number, the gun also has a load mechanism, fire structure and power transmission mechanism for gun movement. The barrel assembly and the lock assembly can be rotated relative to each other. The gun barrel is also specially constructed, consisting of 6 558.8mm steel pipes, connected to a moving chuck thanks to the drive system connected to the engine. Thanks to the electric motor, the M134 has an extremely high firing rate, about 6000 tablets per minute.

M134 Minigun.

When operating, the barrel barrel rotates around the axis, when the first barrel reaches the reload position, a bullet will be inserted into the barrel, the barrel continues to rotate, bringing the first barrel to the position of closing the barrel, then to the position. the firing position to fire the shot, to the unlocked position to throw the shell out . Thus, the gun barrel fired a bullet at every turn, the greater the rotation speed, the firing speed greater. On the other hand, the barrel assembly has many bins, so the firing rate is proportional to the number of barrels. While the first barrel was firing, the second barrel closed, the third barrel loaded, the fourth barrel hit the shell . the guns were fired in a recirculating way one after another. Assuming one turn per second (60 rpm) and 6-barreled gun, the rate of fire will be 360 rounds / minute. In order to perform automatic shooting at a high speed, gun components such as lock, bullet, fire, etc. are linked together through motion transmissions to ensure smooth, continuous work. , synchronized.

M134 Minigun style Slow-Motion.

Minigun uses the power of an external electric motor, in addition to the main engine for the gun, there may be a few extra motors to load the magazine. The gun can operate continuously without interruption because if there is an uneven bullet, one barrel cannot fire, the other guns are still firing normally and according to the rotation of the gun, the bullet will be knocked out. . This is a very important advantage because for a conventional automatic gun, when you encounter a gun bullet, you will stop firing and the gunner will have to manipulate it again. This not only missed the chance to fight but was not easy to implement because the guns on the combat vehicles often placed away from the gunner.

- Watching the M134 Minigun six-cylinder machine gun firing lightning fast

- November 27, 1826 - Match matches are officially born

- Video: 6-barrel machine gun made of elastic elastic wire

- November 18: Begin the end of the 2006 Vietnam Talent Contest

- Japan launches world's largest tunnel drilling machine

- Vending machines know the 'age' of the customer

- Alcatel officially merged with Lucent

- This may be Elon Musk's most terrible money-making machine

- What was the first vending machine launched 20 centuries ago?

- X-ray laser machines are a billion times brighter than today's machines

- Tips for buying a standard washing machine do not need to be adjusted

- November 30, 1924 - The first photo is sent by fax in the world

Biography of hero Vu A Dinh

Biography of hero Vu A Dinh History of hematology

History of hematology Who is Mr. Tam Da 'Phuc-Loc-Tho' and what does it mean?

Who is Mr. Tam Da 'Phuc-Loc-Tho' and what does it mean? Unbelievable facts about the history of the oil and gas industry: Gasoline used to be cheaper than water, so abundant that it had to be dumped into the river...

Unbelievable facts about the history of the oil and gas industry: Gasoline used to be cheaper than water, so abundant that it had to be dumped into the river... Not only producing AK guns, the Kalashikov company also makes drones and anti-terrorist guns

Not only producing AK guns, the Kalashikov company also makes drones and anti-terrorist guns  Former MC of science show MythBusters turns a nerf gun into a 'double-barreled hat', releasing 54 bullets in the blink of an eye

Former MC of science show MythBusters turns a nerf gun into a 'double-barreled hat', releasing 54 bullets in the blink of an eye  Why do pilots shoot guns without dangling the rotor blades?

Why do pilots shoot guns without dangling the rotor blades?  US develops 'unmanned gun' project

US develops 'unmanned gun' project  The shocking truth of Nazi death belts

The shocking truth of Nazi death belts  Special gun - The extremely powerful anti-terrorism weapon of Vietnamese Special Forces

Special gun - The extremely powerful anti-terrorism weapon of Vietnamese Special Forces