Plastic decomposes in seawater faster than paper

Scientists use a "foaming" technique to make CDA plastic more porous, decomposing 65 - 70% in seawater after only about 9 months.

For years, researchers have been searching for the fastest biodegradable plastic in the marine environment, as millions of tons of plastics are washed into the ocean every year. Now, a team of scientists from the Woods Hole Oceanographic Institution (WHOI) has found that CDA is the fastest degrading plastic in seawater , technically classified as a bioplastic. However, they have accelerated the degradation of this material by using a simple modification technique called "foaming" to make it more porous, New Atlas reported on October 18.

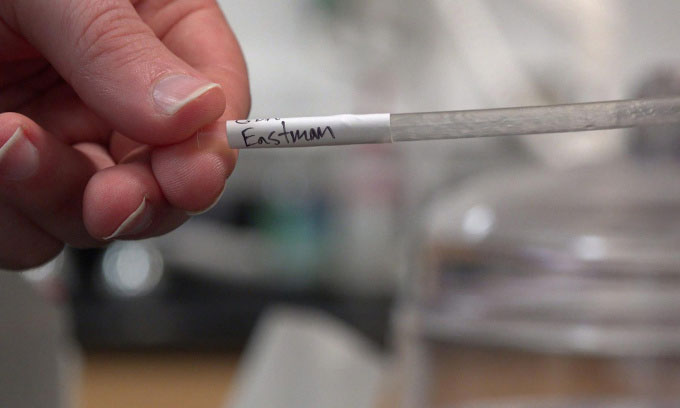

Experimental straws made by Eastman from foamed CDA to test biodegradability. (Photo: WHOI).

CDA, or cellulose diacetate , is made from cellulose, a natural polymer found in plant cell walls, especially cotton or wood pulp. CDA has been around since the late 1800s and is used in everything from cigarette filters (its most common use) to sunglass frames, photographic film, and a million other things we use every day.

In a new study, the team made porous CDA degrade 15 times faster than the solid form, and even faster than paper. The new study was published in the journal ACS Publications.

"We've taken that fundamental knowledge and designed a new material that both meets consumer needs and degrades in the ocean faster than any other plastic material we know of, even faster than paper," said Collin Ward, lead author of the study.

In a 36-week test, when placed in tanks of continuously flowing seawater, CDA foam lost 65 to 70 percent of its original mass. Another common plastic found in every ocean in the world, Styrofoam , did not degrade over the same period.

In the new study, Ward and other WHOI scientists collaborated with bioplastics manufacturer Eastman, which provided materials, provided funding, and is a co-author. The study was conducted in a controlled environment in a laboratory, where the team controlled light, temperature, and other factors to simulate ocean conditions.

The new research will help industries reduce their use of traditional plastics and move toward more environmentally friendly alternatives. The success of the foamed CDA suggests that the material could be used in a variety of products, helping to reduce the amount of non-biodegradable plastic waste in the ocean. Eastman has already produced biodegradable and compostable trays from foamed CDA that can replace conventional foam meat packaging trays, which do not biodegrade in any natural environment, whether on land or at sea.

- New plastic material decomposes faster

- Creating plastic can decay in seawater

- Paper bags are only good for the environment when reused 43 times

- Video: How to create a blade with plastic and wood cutting paper

- Packaging can be used long term?

- Young girl preparing plastic bag that decomposes in a few weeks from skin and fish scales

- Plastic 'paper' printer

- Corals 'eat plastic' adds to environmental concerns

- Decomposing ocean plastic produces toxic chemicals

- The paper can be rewritten several times

- Successfully developed bioplastics suitable for industrial production

- Paper bottles are better than plastic

Is the magnetic North Pole shift dangerous to humanity?

Is the magnetic North Pole shift dangerous to humanity? Washington legalizes the recycling of human bodies into fertilizer

Washington legalizes the recycling of human bodies into fertilizer Lightning stone - the mysterious guest

Lightning stone - the mysterious guest Stunned by the mysterious sunset, strange appearance

Stunned by the mysterious sunset, strange appearance