Production of nylon - 6 environmental stems

Researchers at the University of Cambridge, UK, have found a method of synthesizing environmental stems to make caprolactam, precursors of nylon-6, from cyclohexanone.

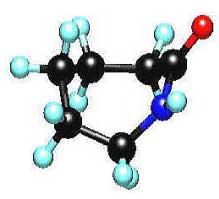

Caprolactam molecule

(Photo: tennoji-h)

Nylon-6 is widely used in industrial applications with increasing demand. However, the two-step process currently used to produce nylon-6 from cyclohexanone must use highly active substances. These substances produce large quantities of waste ammonium sulfate.

Caprolactam is produced in a one-step process, does not use solvents but only uses air as oxidizing agents, ammonia and nanoscale aluminum crystals as catalysts.

These catalysts contain separate acid and redox positions, allowing the conversion of cyclohexanone to caprolactam with an efficiency of up to 78% at 80 ° C easily.

Robert Raja, one of the researchers, said that the open structure of these bipolar solids allows substrates to easily access active sites and products that can easily diffuse away from porous structures. microphone size.

Neville Hargreaves of Crystal Faraday, UK, said it was a real innovation, but it still depended on how to apply it on an industrial scale.

- The EU plans to cut 80% of nylon bags by 2019

- On World Environment Day 5-6: 'Assassin' nylon bag

- Strong with 'white pollution'

- New technology to make bicycles from nylon

- The first Latin American country banned the use of nylon bags

- Banana stalks and incredible benefits

- The country boycotted nylon bags so much that it was ready to imprison anyone who used it

- India: Severe storms, 8 deaths, 8000 evacuees

- New Zealand prohibits the use of disposable plastic bags

- Europe charged with plastic bag death

- Learn production processes and nuclear bomb power

- Making nylon from cassava

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light