Rice husk is a clean construction material

Using rice husk as electricity generation material not only does not cause pollution, but the amount of ash obtained after burning is not small. Torftech Group of England said that after burning each ton of rice husk, it will produce 180kg of ash, worth 100 USD, can be used as an additive for cement and can directly replace SiO 2 in cement .

Naturally, scientists have long discovered that rice husks are valuable when used as construction materials. In rice husk contains a lot of SiO 2 content, but this is the main component in cement, but people want to make use of the ash obtained after burning rice husk as a substitute for cement, this method will create Carbon content in rice husk ash is very high, it is not possible to replace cement components.

Recently, according to Discovery, under the support of social science funds, US scientists have discovered a new method of processing rice husks, which can simultaneously use rice husk ash as an internal ingredient. cement, promote the development of clean construction materials.

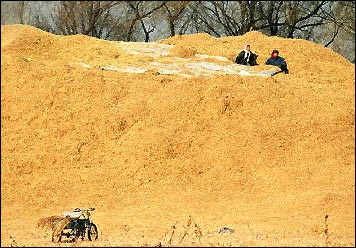

Rice husk (Photo: TuoiTreOnline)

Rajan Vempati, general manager of the US-based CHK Group in Texas, said they have now teamed up with a research team and found a method that is almost no longer Carbon in rice husk ash. This new method is to put the rice husk in an incinerator, burn it at a temperature of 800 ° C, finally leaving only high purity SiO 2 particles. At the conference on clean chemicals and construction held at the University of Maryland Park, Vempati, along with his research team, introduced their research results.

Vempati said: ' Even in the combustion process, CO2 will be generated, but generally it is neutral carbon, because the amount of carbon will be annihilated by the annual new rice product that will absorb them. '

In fact, the use of concrete and consumption poses a difficult problem when causing climate change. Every ton of cement used to produce concrete, it must be released into a ton of CO2. Within the world, cement production accounts for 5% of carbon emissions in all human activities.

Mr. Jan Olek of Purdue University said: ' The reason that the rice husk ash cannot be the main ingredient in cement is because the carbon content is too high. If this problem can be solved, rice husk ash will become a good material for concrete, thereby reducing the amount of carbon emitted from the concrete industry. '

Research results show that in concrete, if more rice husk ash will be stronger and more resistant to erosion . The team predicts, the repair of high-rise buildings, bridge piers or any construction near the sea or on the water, if using rice husk ash to replace 20% of cement, it will be very effective. High for concrete.

Vempati's team is currently conducting an experiment, if it is possible to demonstrate the method of burning rice husks at high temperatures effectively, they will mobilize capital to start building large-scale kilns, and is expected to Production of rice husk ash with an output of 15,000 tons / year.

If the production of rice husk ash is stable, taking advantage of all the rice husk sources in the US, then the rice husk ash of 2.1 million tons / year can be obtained, the team added. In fact, for developing countries that consume huge amounts of rice and concrete such as China and India . the development potential of rice husk ash is huge.

- Press rice husk into high quality fuel

- Clean water filter device from rice husk

- Fabrication of insulation from rice husk

- Successful production of rice husk firewood

- Technology to produce tires from rice husk ash

- Philippines: Gas stove is made of environmentally friendly rice husk

- Vietnamese scientist finds the inhibitor of invasive weeds from rice husk

- Technology to turn rice husk into ... wood

- High quality fuel from rice husk

- Vietnam produces fireproof and bulletproof paints made from rice husk

- Use rice husks to produce electric batteries

- White rice and brown rice, which is more nutritious?

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light