New helmet lining material: Lighter, better absorbing, cooler

A new material developed at HRL Lab, California, USA promises to change the current helmet structure.

This material is light, dry, wearing a hat without being stuck like it is now.

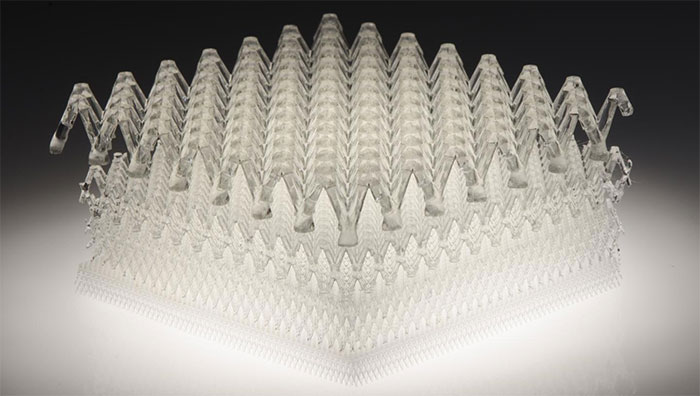

This material allows better absorption of force in the event of an accident, but is lighter and more dry, wearing a hat that is not clogged as it is now. When tested, the polymer frame with a structure similar to the Eiffel Tower absorbs 27% better force than the best polystyrene foam on the market now, 48% better than the highest grade vinyl nitrile foam.

To create this new helmet lining, scientists used liquid plastic and UV-acting. Under the action of ultraviolet rays, liquid plastics form different polymer structures, which can fine-tune the hardness and elasticity of the pads.

This technology can be used not only in helmets, but also as a shockproof packaging for electronics, or as a car interior lining. However, the technology for making polymer pads is being prepared to be commercialized for sports helmets such as rugby and cycling.

- New shockproof helmet

- Helmet heard the thought

- 3 in 1 helmet

- MindRider - Helmet reads the driver's ability

- Helmet invisible

- Paper helmets can be folded

- Intelligent helmet auto-rescue

- Launched the world's first folding helmet

- Smart Helmet saves unconscious driving

- High-tech helmet

- The helmet reads the driver's mind

- The darkest material can swallow most of the light

The US company is about to build a supersonic passenger plane of 6,000km / h

The US company is about to build a supersonic passenger plane of 6,000km / h Japan develops avatar robot as in fiction film

Japan develops avatar robot as in fiction film Australia tested the world's first mango picking robot

Australia tested the world's first mango picking robot America develops technology to separate water from animal waste

America develops technology to separate water from animal waste