New technology turns waste plastic powder of electronic circuit boards into building bricks

The research team of Ho Chi Minh City Food Industry University has reused plastic waste powder from drilling process, cutting production of electronic circuit boards for concrete construction applications.

The strong development of science and technology in recent years and in the future requires increasing demand for electronic board production.

In parallel with the socio-economic development, waste is also a matter of great concern, one of the wastes generated from the process of producing plastic powders mixed with or without metal components. hazards of economic value such as gold, copper, lead, iron, aluminum, nickel, silver, tin . The characteristics of this plastic powder are not yet clearly defined about the hazardous properties but the size is fine and important. light weight, large storage volume and quite expensive in the process of collecting and processing.

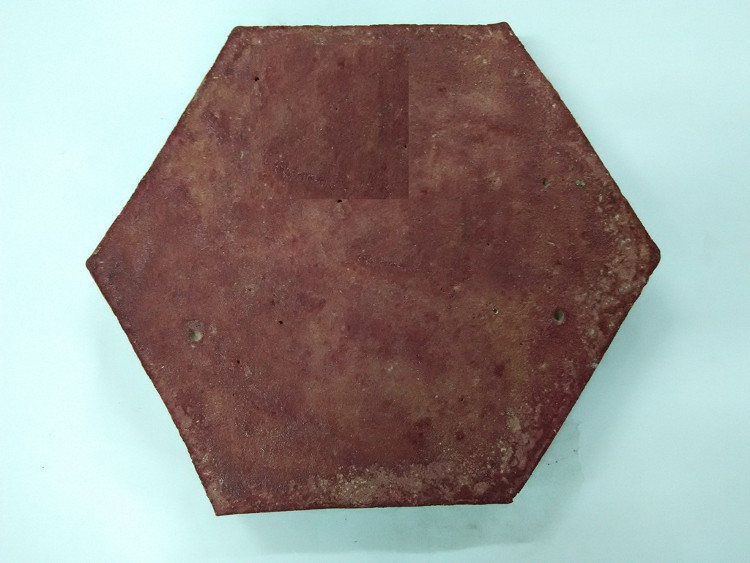

Concrete brick from waste plastic powder.(Photo: Thanh Diem).

Taking advantage of light and fine grain characteristics, the authors include Master Ngo Thi Thanh Diem and the final year students of Ho Chi Minh City University of Food Industry and conducted research on reuse of waste plastic powder and Recycling into products that are useful for society but still ensure the environmental requirements when used.

Accordingly, the study has investigated the possibility of reusing plastic waste powder from drilling process, cutting production of electronic circuit boards for application of concrete bricks in construction and comparing them with the same product groups according to Vietnamese standards (TCVN). Initial research results showed that by solidification method of solid waste treatment, curing products from waste plastic powder almost meet well the allowable copper leakage according to toxicity extraction method (TCLP). ), high compressive strength for cement curing products with cement mixing ratio: waste plastic powder is 70:30 and water ratio: cement is 55: 100.

Re-use waste plastic powder from cutting drilling circuit boards for concrete brick applications in construction.(Photo: Thanh Diem).

The model of cured concrete bricks from waste plastic powder is in conformity with TCVN 6477: 2011, the required compressive strength is greater than 5 Mpa and the water absorption is less than 14%. In addition, cured concrete bricks products from waste plastic powder also result in copper leak analysis that satisfies the environmental requirements of EPA (less than 100 mg / L).

In the future, the research team will diversify recycling products to recycle and reuse this waste plastic powder.(Photo: Thanh Diem).

On the next research direction in the coming time, MSc. Thanh Diem said, the team will conduct research on the separation and thorough recovery of precious metals before conducting curing. At the same time, the group also tested the application of additives other than cement to enhance curing efficiency, diversify recycled products to recycle and reuse this plastic waste, to contribute a part to the work. general environmental protection for the community.

- A company has found a way to turn waste plastic into bricks to build houses and protect the environment

- Video: Turning ocean waste into building bricks

- Ecobrick project: recycle plastic for building bricks, the most effective solution at the moment

- Producing bricks from ... plastic waste

- It turns out we all wash the cutting board the wrong way

- The technology turns plastic waste into edible fungus

- The danger of 'death' stalks from using plastic cutting boards

- Build a brick house made of paper

- How long does it take for plastic waste to decompose?

- Turning plastic into petroleum: 2-in-1 solution for plastic waste

- Why are most printed circuit boards green while Apple is black?

- Vietnam is the top 5 countries that discharge most plastic waste into the sea

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light