Mars soil could be used to 3D print rocket parts on the Red Planet

Many researchers are trying to figure out how to make materials on Mars, and a new study has found a way to make titanium alloys using the regolith (topsoil) of Mars.

Since the beginning of space exploration, nearly every aspect of space activities has remained very expensive. For example, NASA's space shuttle costs about 54 000 dollars to put a kilogram of payload into Earth orbit.

According to a statement by NASA and the Artemis and Gateway missions, human settlement on the Moon will take place as early as 2024 by sending the first human crew to the Moon's surface. Using on-site resources to sustain human exploration could make extraterrestrial missions more efficient with reduced logistical challenges.

The ability to manufacture and repair structural components in space is crucial for future space missions to the Moon, Mars and beyond to the International Space Station. To realize this idea, additive manufacturing (AM) techniques can fabricate structures from the bottom up and layer by layer using locally available resources.

Furthermore, if structural components or coatings can be manufactured using on-site resources, it would reduce the mass burden required by extraterrestrial missions. AM's ability to manufacture custom structures with different designs makes it an intriguing approach to space exploration towards future human or robotic expansion missions.

In situ resource utilization (ISRU) has been realized using several AM techniques such as photomolecular reactions, powder fusion, directed energy deposition (DED) and fused deposition modeling to prepare create structures based on different materials, available on Mars/Moon.

However, the powder-based AM method faces different microgravity challenges than other techniques, such as powder contamination by floating metal powders and keeping the powder flowing at the laser point. ; therefore, technologies must be developed to address these problems to enable large-scale metal production.

Topsoil (regolith) is a layer of heterogeneous, loose material that covers a hard rock bed. This layer includes dust, soil, debris and other related materials and is present on Earth, the Moon, Mars, and other planets. This layer almost covers the entire Moon.

Accordingly, a team of scientists at the WM Keck Biomedical Materials Research Laboratory, School of Mechanical and Materials Engineering, Washington State University, Pullman, Washington, USA conducted a new study through the use of regolith to create pottery and also mixing it with the titanium-aluminum-vanadium alloy. The alloy is known for its extreme strength and resistance to corrosion, and the team was very interested in adding a Martian soil to it to see if it would improve things.

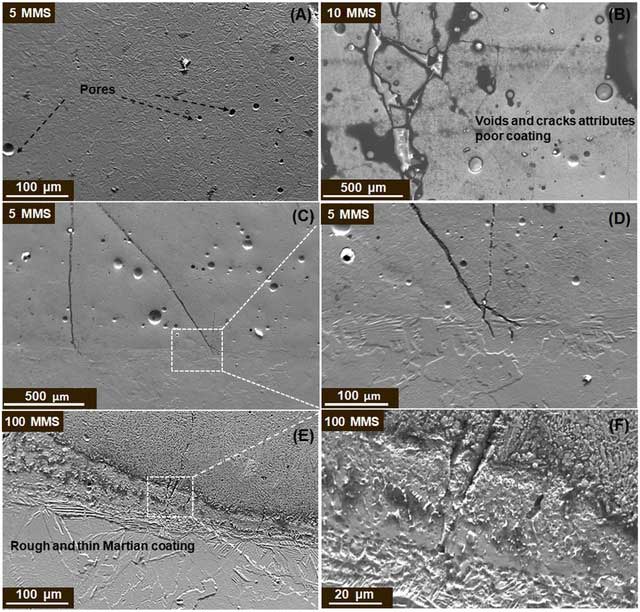

The creation of 100% regolith ceramics was not really successful in practice. They tend to crack when cooled and although not useful as a building material, can be used as a protective coating from oxidation and can even reduce radiation. Mars has no magnetic field, so it is less protected from the solar wind and cosmic rays. It could also produce some pretty unique auroras on Mars.

But regolith can be used to make a fairly sturdy material. When a small fraction of regolith (5%) was mixed with a titanium alloy, the team found that it significantly improved the material's properties and made it much lighter.

Study co-author, Amit Bandyopadhyay, from Washington State University, said: 'It gives you a better material, with greater strength and stiffness, to be able to perform significantly better in Some applications".

The team created the 3D printed composite by melting the alloy to more than 2,000 degrees Celsius and adding simulated soil. The mixture then flows onto a moving platform that allows the researchers to print objects of specific sizes and shapes.

This approach still requires a lot of material that needs to be brought from Earth, but as the team says, it's a first step. Future work could make it possible to create even better composite materials and use 3D printing techniques more efficiently.

Bandyopadhyay added: 'This proves that it is possible, and perhaps we should think in this direction because it is not only possible to make plastic parts but also very metal-ceramic composite parts. durable and can be used for any type of structural part'.

This is not the only way to use regolith on Mars. Other researchers have found a way to mix it with blood or waste to make sturdy bricks.

- Earthworms can grow well in Martian soil

- Arduous take Mars land to Earth

- Mars was once warm and rainy

- Did the ocean on Mars get into the rock?

- 9 surprising facts about Red planet

- Mars soil may have live bacteria

- Brick from soil simulating Martian soil: stronger than concrete

- Overview of Mars

- Mars used to be 'green planet' like Earth

- The soil on Mars is similar to that of the Hawaiian Islands

- How is Mars different from Earth?

- China is set to launch the Mars probe in July

Announced 3 houses on the Moon and Mars

Announced 3 houses on the Moon and Mars Science proves: Mars also knows 'deflated'

Science proves: Mars also knows 'deflated' Elon Musk announced the price for a Mars trip was 11.6 billion VND, free of charge

Elon Musk announced the price for a Mars trip was 11.6 billion VND, free of charge NASA discovered strange 'gate' on Mars, is the hiding place found?

NASA discovered strange 'gate' on Mars, is the hiding place found? Revealing the first city on Mars, with enough space for more than 250,000 people to live

Revealing the first city on Mars, with enough space for more than 250,000 people to live  We could start building a colony on Mars with just 22 people!

We could start building a colony on Mars with just 22 people!  Amazing discovery of 4.5 billion year old alien ocean of life

Amazing discovery of 4.5 billion year old alien ocean of life  Mars' Surprising Effect on Earth's Oceans

Mars' Surprising Effect on Earth's Oceans  Was there nuclear war in ancient times?

Was there nuclear war in ancient times?  What happens to dead bodies on Mars?

What happens to dead bodies on Mars?