Sears Tower

-

Construction time: 1970 - 1974

-

Location: Chicago, llinois, USA

The Sears Tower marked the pinnacle of skyscraper development in the United States for more than 20 years, keeping the record of the world's tallest building, 110 floors that fainted at an altitude of 443m, which is an impressive limit on the sky. Chicago business district, the city opened for many initiatives in building high-rise buildings.The tower was designed for Sears, Roebuck and the Company, trading post-order sample books, consolidating 7000 employees of the company in the same office.Sears acquired a block of houses in the city and ordered Skidmore, Owings & Merrill (SOM), an international company of architects and engineers to design the building.

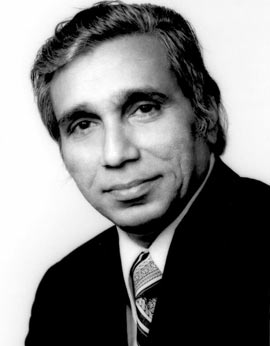

Structural engineer Fazlur Khan Fazlur Khan Structural Engineer (Photo: fazlurrkhan.com)

SOM's group is led by c architect and structural engineer Fazlur Khan.Together with architect and engineer Myron Goldsmith, they built a reputation in designing high-rise buildings.Applying the computer-aided method of quantitative structural analysis, the first conception concept of pregnancy is a generation of skyscrapers of unprecedented scale, far beyond the limit of calculation. feasible in terms of structure or economy before.

Braces and bundles

The higher the building, the greater the impact of the wind.In order to neutralize wind loads, smaller-scale structures are often hardened by cross-walled walls or walls cut around staircases or elevators.However, using this method to brace the steel frame to obtain appropriate stiffness in high-rise buildings is very expensive.Therefore, the concept of the new structure must be developed for such buildings using the same amount of structural materials as conventional buildings and therefore does not incur costs for elevation.In 1971, the 100-storey John Hancock Building in Chicago adopted the new concept of Fazlur Khan's " bracing " with the cross-bracing system in the perimeter of the frame instead of the central core.

Sears did not want to see the cross-bracing system in the facade of the building, but also had to meet a wide range of floor sizes, both of which had to satisfy their own requirements for very large slabs and create areas. Smaller for a tenant in a building.In order to meet these requirements, Fazlur Khan developed the concept of " bundle pipe " structure.Instead of making small-scale lateral braces of the core or on a large scale of the building's perimeter, Sears Tower is a bundle of medium-sized tubes, in a separate tower sense - linked together.Higher than 30% by John Hancock Building, the structure of Sears Tower is only 14% heavier.

In the foundation, the tower consists of nine tubes, each with a square edge of 22.9m, raised with different heights: one stop on the 50th floor, two on the 66th and third floor on the 90th floor, only two remaining pipes to the last 20 floors.In addition to being slimmer and seeing lighter when the building was built high, this solution made the floor area changed from 3800 to 1100m 2 (41,000 to 10,000 square feet).

Each tube has no inner column to create the full flexibility of office layout and frame by steel columns on four sides in 4.6m centers linked by circumferential steel beams.Instead of frame bolts with cross-bracing systems reduce the flexibility of the inner ground, the frame only has vertical and horizontal components that are hardened by the connection entirely by welding.Columns and beams create components consisting of welded steel plates in the shape of a cross section. The thickness of the plate changes from 25mm at the top of the building to 100mm in the background, where it loads itself Best.Upper steel structure overlaps with 1.5m thick concrete coating placed on the submerged foundation below.These submerged concrete foundations in steel casing vary in diameter from 2.2 to 3m and average length of 20m to the base stone.

(Photo: free.fr) )

Materials and construction

Actual data:

-

Length: 443m, 520m add antenna mounting part

-

Total area of premises: 409,000m 2

-

Weight: 222,500 tons

-

Manpower: 16,500

-

Cost: $ 150 million

Steel structure upstream pre-engineered into modules of size 7.6 x 4.6m - maximum size can be transported by truck to the construction site.Each module - consists of a two-storey column with half-welded long beams at the workshop mounted on both sides.After using the pivot machine to put in the right construction location, welds connecting beams with mid-span beams are bolted right at the construction site.By reducing 95% of the welding process, the frame is built very fast at 8 floors per month, saving a lot of work.

To increase the rigidity of the building, the pipes connect to each other along the columns and beams associated with adjacent modules.In addition, the tubes were connected by two-story braces around the circumference of the bundles on the 29th-31th, 64th-66th and 88th-90th floor. house, acts as a structural wall.Concrete slabs in corrugated steel sheets are placed on 1m deep braces.Each bracing is bolted directly to the column, making the structure more efficient by avoiding indirect transfer of floor load through the main beams.The direction of the interlacing intervals in each of the six floors (floors) to balance the load on the perimeter pipe frame.

Sears Tower belongs to a generation of very tall buildings that require development

New texture concept to resolve wind loads. (Photo: Northwestern)

Sears Tower has 102 elevators serving staff, vertically divided into 3 areas, each with 30 to 40 floors, with two scenic corridors located on the bottom floor of each area.16,500 tenants moved to the hallway to see the scene as quickly as 14 two-stage speed lifts and loads of people.From these points, passengers move to local slopes to reach the floor they want.The lobby watching the public scene on the 103 floor was served by two express lifts, bringing guests from the ground floor straight up to the 103 floor, with speed of 9.15m per second.

In addition to marking a significant progress in optimizing structural systems for high-rise buildings to increase the height of buildings, Sears Tower is an example that illustrates the method in which modernity of the International Style likes. The United States must become a symbol of cooperation power.Perfectly built-up walls with glass on black and copper colors have not yet spoken, and do not indicate what structural skills help the building reach a height previously not reached.

- January 28: The Eiffel Tower was started but the French protested

- Change the name of Big Ben tower to Elizabeth tower

- B3 Cham Tower My Son cracked and tilted

- Japan will have the highest television tower in the world

- Big Ben clock tower will stop for 4 years

- The famous London clock tower was officially renamed

- 10 interesting things about the Eiffel Tower celebrating 125 years old

- 15 interesting secrets about the Eiffel Tower

- View from soaring glass bottom observatories

- 11 interesting things you can know about the Big Ben clock tower

- March 31, 1889: Inauguration of the Eiffel Tower in Paris

- Uses of the water tower

Norway built the world's tallest wooden tower

Norway built the world's tallest wooden tower Kremlin

Kremlin Ashurbanipal: The oldest royal library in the world

Ashurbanipal: The oldest royal library in the world Decoding the thousand-year construction of Qin Shihuang shocked the world

Decoding the thousand-year construction of Qin Shihuang shocked the world