Unexpected effect of cooking oil on industrial food production equipment

Food made in industrial style will be a thousand times cleaner, thanks only to this extremely effective technology.

Food processed on huge industrial chains is the product of dozens of raw materials, thrown into giant stainless steel machines. Normally, these machines are very difficult to wash and when the food processing unit has scratches, the bacteria will have a wonderful place to live.

For us, these surface scratches are very small, not bothering but for the naked eye bacteria we can't see, the scratches are the giant "natural" valleys that make the house in. Food trapped in these slots will again become food for bacteria, the risk of infection of the entire chain increases.

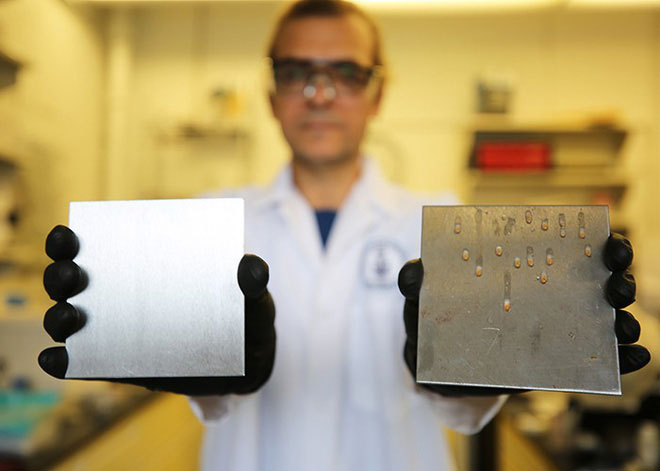

With just a layer of cooking oil, the scientists reduced the level of bacteria to the surface by 1,000 times.

Professor Ben Hatton, Dr. Dalal Asker and Dr. Tarek Awad have come up with a cheaper, safer and more effective way to prevent bacteria from living in these expensive food making machines. Minimizing infection on the device will ensure safer food. They propose a very simple way that is very easy to implement, considering the service industry of the above system: it is covered with a thin layer of oil on the surface of the metal , filling the scratches, the slots cracks appear during machine operation.

On their tests, scientists reduced the bacterial surface level by up to 1,000 times with just a thin layer of edible oil. Research results were published in the scientific journal ACS Applied Materials & Interfaces.

Cooking oil can often prevent bacteria from attaching extremely effectively.

"Covering stainless steel surfaces with regular cooking oil can effectively prevent bacteria from attaching , " Professor Hatton said. "Oil covers the female slots, creating a waterproof layer and acts as a barrier against impurities on the equipment surface". Currently, the professor is working with AGRI-NEO, a grain processing company that is eager to find a solution to address this problem.

Simple, efficient and low-cost technology is based on the principle of Slippery Fluid Combination (SLIPS) , developed at Harvard University, with the aim of attaching a lubricating surface to a micro structure to Create a smooth, waterproof and non-stick surface. Cooking oil such as olive oil, corn oil or canola oil will give us a way to prevent plaque much safer, when no more toxic chemicals are needed.

But even chemicals can not completely remove all bacteria: difficult to clean the machine is the first problem, the second is that bacteria can build resistance to bleach over time.

From left to right: Dr. Tarek Awad, Dr. Dalal Asker and Professor Ben Hatton.

"Contaminated food from equipment will be able to affect consumer health, causing economic damage when recovering defective products that food can continue to infect, even if the equipment is cleaned and cleaned. will be chemical , " Professor Hatton said. "This study shows that using a simple surface treatment such as cooking oil, we can create a barrier that minimizes up to 1,000 times the level of microbial contamination on the surface."

Hatton's team continues to test different compounds, oils and foods, to create even more effective diaphragms. Discovering the wonderful use of a daily item, we feel that everything around us has the ability to change people's lives in a good way.

- Food experts advise you not to eat the following 6 dishes

- Use industrial feed for commercial snakehead fish

- 6 healthy cooking oils

- How to use the most beneficial cooking oil

- 10 golden rules to avoid food poisoning

- 4 cooking habits are easy to cause cancer

- Successful production of seed crabs with industrial feed

- Harmful effects of cooking oil on the body

- Cooking methods are harmful to health

- Advanced technologies help detect dirty food

- The habit of using oil wrongly can easily lead to liver cancer

- Regular cooking can live longer

'Fine laughs' - Scary and painful torture in ancient times

'Fine laughs' - Scary and painful torture in ancient times The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why?

The sequence of numbers 142857 of the Egyptian pyramids is known as the strangest number in the world - Why? History of the iron

History of the iron What is alum?

What is alum?