3D biological printing, pharmaceutical industry revolution

3D bio-printing not only creates implants on the human body but also opens new avenues for pharmaceutical manufacturing companies to be able to replace long-term animal experiments.

Body organs such as kidney, liver and heart are extremely complex tissues. Each cell is made up of many different types of cells and together with other components to function and create separate structures.

In order for biological agencies to be able to print these agencies, 3D printers must mimic their activity in nature - both in terms of arrangement and biological needs. For example, the kidneys must treat and discharge waste in the form of urine.

Organ transplants are not the most important outcome of this new study. There is evidence that 3D cell printing technology is extremely useful in developing drugs. This promises to reduce animal experiments when new treatments are introduced, while the supply of drugs to the market is faster and safer.

How to print 3D biology?

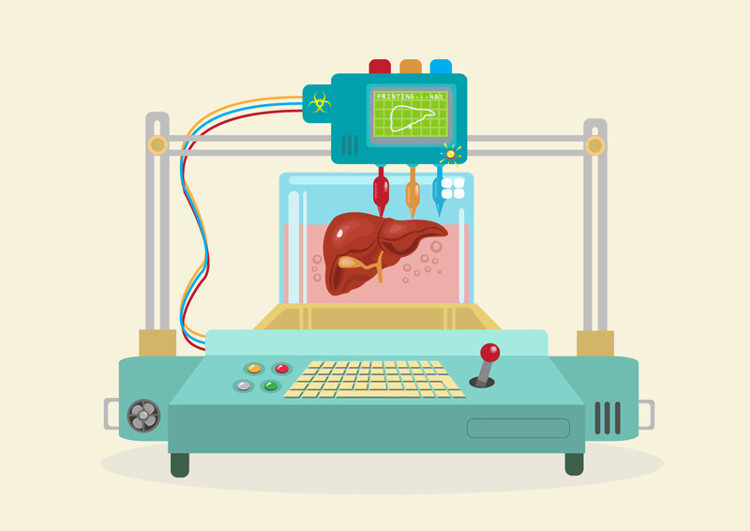

3D printing or large fabrication is a series of different stages that are combined to create a three-dimensional object. In medicine, "biological" printing takes cells into print to create human organs for transplantation.

3D biological printing requires sterile conditions to avoid contamination of printed materials and temperature, humidity must be appropriate for cells not to die. In addition, conventional plastic materials used in 3D printing cannot be used in biological printing because they require printing at high temperatures or containing toxic solvents.

Researchers around the world are developing materials that can be manipulated in 3D printers and do not cause much damage to cells. However, each type of cell requires a unique mechanical environment to function normally.

Development of 3D biological printers.(Photo: Crystal Eye Studio).

For example, the bone is a tough and durable material, the heart muscle is elastic, the internal organs like liver are soft and compressible.

In a recent statement, the researchers said: 'New materials extracted from marine algae can be used to print 3D artificial stem cells in a separate environment and without harming cell. We believe that this discovery paves the way for printing complex tissue structures. "

Hope for patients

Currently, patients who need to replace organs must wait a long time to have an implant and then have to take immunosuppressants for the rest of their lives. This causes side effects and consumes a huge cost to the health system.

The development of 3D printed biological tissues to replace damaged organs is expected to provide a new solution for 1,500 patients in Australia each year. But printing entire organs in the body is an extremely complex process, it can take up to a few weeks, while patients cannot wait.

Previously, researchers have been printing simple tissues like skin. The next phase of this technology requires the combination of nerves, blood vessels, lymphatic vessels and must be suitable for the body to create transplantable organs such as kidney, lungs, heart or liver.

Perhaps it takes us years and millions of dollars to print the entire organ in the human body. But there is another way that renewable cells can be used, namely: testing new drugs in the lab.

The cells are printed for drug testing

Currently, to bring a new drug into the market is estimated to cost $ 2.5 billion, and it may take more than ten years from the beginning to the end. Even new drugs are identified, their ability to accept is very low: in 2016, less than 10% of new drugs are approved.

At the beginning of human clinical trials, the probability of a drug to market it is between 10 and 15%. However, this method can be fatal for participants.

The experimental drugs failed mainly because of poor efficacy in humans although the results of animal tests were very positive. This is due to differences between species: rodents and test animals differ from humans in many main points.

Therefore, this 3D printing technology allows us to print complex 3D models of liver, kidney or heart muscle, suitable for testing and identifying pharmaceutical molecules at the experimental stage. These models have begun to be used by multinational pharmaceutical companies.

While the use of animals in the study remains inevitable, the US Food and Drug Administration recently began to consider the use of 3D biological printing products to replace the methods. Current pharmaceutical testing.

- Research three-dimensional biological printers producing kidneys

- The new biological printing method helps create tissue containing vascular networks

- 3D printed organs bring hope of cheap transplants

- What is Industry 4.0 Revolution?

- 3D printing artificial leather - a new step for cosmetics industry

- The first pharmaceutical to use licensed 3D printing technology in the United States

- 3D printing gets both corneas and implants successfully, people really come to the future

- Print human blood vessels with 3D printers

- History of book publishing industry development

- Biological ink breakthrough 'in' human body parts

- Organ transplantation ... 3D printing

- 2006 - The year of prosperity of the digital printing industry

Green tea cleans teeth better than mouthwash?

Green tea cleans teeth better than mouthwash? Death kiss: This is why you should not let anyone kiss your baby's lips

Death kiss: This is why you should not let anyone kiss your baby's lips What is salmonellosis?

What is salmonellosis? Caution should be exercised when using aloe vera through eating and drinking

Caution should be exercised when using aloe vera through eating and drinking 3D printing solution to build a school quickly in a war zone

3D printing solution to build a school quickly in a war zone  New 3D printing technique is 30 times faster than traditional methods

New 3D printing technique is 30 times faster than traditional methods  What will a house made from 3D printing technology look like?

What will a house made from 3D printing technology look like?  3D printed heart tissue can keep beating for 6 months

3D printed heart tissue can keep beating for 6 months  For the first time producing drugs using 3D printing technology in just 7 seconds

For the first time producing drugs using 3D printing technology in just 7 seconds  US printed 3D nuclear reactor core

US printed 3D nuclear reactor core