Nanotechnology helps increase thermal efficiency

Advanced Nano technology foreshadows a new era in heating, cooling & power generation technology in general.

Researchers at Boston University and Massachusetts Institute of Technology (MIT) have used nanotechnology to make major improvements in the ability to increase thermal efficiency, which paved the way for a generation of new products - from semiconductor devices, air conditioners, exhaust systems on cars as well as technologies that use solar energy - help operate cleaner.

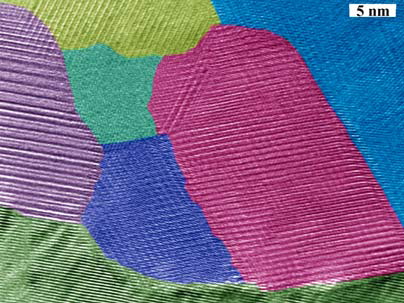

Cross section of oblique crystallization of Bi - Sb - Te particles with nanoscale in alloy mixture, viewed under an electron microscope.The light colored arrays characterize each type of particle in a semiconductor mixture.The team of researchers from Boston University and MIT using nanotechnology to create new material structures has led to a major improvement in the ability to increase thermal efficiency.(Photo: Boston College, MIT, and GMZ Inc)

The team used a low-cost, detailed explanation of the online publication on the Journal of Science, which involves the construction of nanostructures made up of a mixture of alloys. with very small size, to be able to meet in micro chillers & generators. The researchers said that in addition to the cost of producing this material very cheap, their method will bring practical results, in the short term can be applied in low energy consumption products. or take advantage of wasteful energy sources due to the operation of discharged machinery systems without reuse.

Achievements represent an impressive milestone in the process of finding steps to improve performance in the thermal power industry, as this both entices and discourages many scientists. Since the discovery of thermoelectricity in the 19th century up to now. This implies certain materials that convert heat into electricity and vice versa. But they have stumbled into a deadlock when trying to improve efficiency: most of the materials have both led and heat, so the temperature between them is balanced very quickly. To improve efficiency, scientists have tried to obtain materials that can conduct electricity but do not correspond to thermal conductivity.

Application of nanotechnology, researchers at BC and MIT Laboratories have achieved great results in the ability to increase the thermal efficiency of semiconductors with the basic components of element Tellurium (Te) and two Other nonmetals are Bismuth (Bi) and antimony (Sb) [i] - in bulk - a semiconductor alloy mixture commonly used commercially since the 1950s. Specifically, the team did adding figure of merit: also known as quality factor, quality index, which is 40% in this form of alloy, this is a performance limit of materials that scientists have measurable.

The simple closed circuit module proposed by researchers at Boston University and MIT aims to validate how a semiconductor alloy is redesigned in a large block, achieving significant performance improvements. productivity.This material serves as a milestone in the field of thermoelectricity research, providing many applications in everyday living products, from semiconductor devices to air conditioners, car exhaust systems. solar technology or technology - help them operate cleaner.(Photo: Science / AAAS)

This achievement marks an important acceleration in the half-century of applying the benefits of semiconductors, which is the ability to operate within a temperature range of up to 250 degrees C. This is a successful step to use. alloys are relatively cheap and environmentally friendly, in the form of large blocks, meaning this discovery can quickly be applied to large-scale applications, strongly influencing cooling & consumption equipment. electricity in general.

'Using nanotechnology, we have found a way to renovate old materials by disintegrating them and rebuilding them in a mixture of nanostructures in bulk form', Zhifeubf Ren - scientist physics at Boston University & one of the project leaders said. 'This method is low-cost and can be widely used in mass production products. This is a stimulating opportunity to take advantage of the performance of thermoelectric materials to maximize profits. '

'Electricity-generating materials have been used in many applications, but this better material can have far greater impacts,' said Gang Chen, Warren and Towneley Rohsenow - professors at the Faculty. Engineering at MIT & also project leaders said.

The 'hot and cold' problem of thermal power is a problem in the mind that physicists are trying to solve. For example, heating the end point of a wire, will cause the transfer of [electron] particles to a cooler head, which generates an electric current. Conversely, providing a similar current in a wire will result in heat generated from hot areas spreading to cold areas. Phonon, a type of quantum vibration that plays a key role because it is the basic principle in thermal conductivity in non-conductive solids.

Bi - Sb - Te semiconductor alloy is a commonly used material in thermoelectric generating products, researchers crush them into molecular particles (nanocopic dust) and set up leave them in large blocks, forming nano scales. These oblique fish structures and non-regular arrangements of the alloy will dramatically reduce the motion state of the phonons in the material, radically altering the electrical generation efficiency by clogging. thermal currents while allowing current to flow.

In addition to Ren, there are six researchers at the BC laboratory, the international team of MIT researchers: Chen; Mildred S. Dresselhaus - technical lecturer; Bed Poudel - research scientist at GMZ Inc Energy Company; Junming Liu, a physicist from Nanning University - China.

The materials that produce electricity by temperature differences have been used by NASA to generate energy for spacecraft in journeys far away from Earth. This material is also used in special seats in cars, helping drivers feel cool in the summer. The automotive industry has experimented with many methods of using thermoelectric materials to convert waste heat from automobile exhaust systems to useful electric current.

The research is supported by the Department of Energy (MIT) & the US National Science Foundation.

Note

• [i] : This semiconductor compound Te - Bi - Sb consists mainly of Telua and two auxiliary components are Bi, Sb.

- Increase the efficiency of photosynthetic reactions with nanoparticles

- Nanotechnology and applications

- Planting trees in rooms helps employees feel more comfortable

- How does a thermal camera work?

- China invented 'stealthy' materials with thermal cameras

- Learn about nanotechnology in industrial production

- Implant carbon nanotubes into plant cells to increase photosynthetic efficiency

- Golden rules help you to

- 'Improved' ways to increase efficiency

- Thermal shock: Danger of life when riding in a sunny car

- Nanotechnology and applications of nanotechnology

- Paint smart

'Barefoot engineer' invents a pipeless pump

'Barefoot engineer' invents a pipeless pump Process of handling dead pigs due to disease

Process of handling dead pigs due to disease Radiometer

Radiometer Warp Engine: Technology brings us closer to the speed of light

Warp Engine: Technology brings us closer to the speed of light